Precision, high speed, repeatability, and simplicity are some of the qualifications we used for our hole-making equipment. It is with this thinking that our patent pending technology came to light. It is now available across our full range of PIL micro-drip irrigation configurations — from the /Enter to the ///Explore lines.

Fast and reliable drilling

After major efforts, our product development team has come up with a series of innovative answers for making holes. They opted for a mechanical drilling method driven by a high-performance motor in order to reach unheard rates. With our lines combining short drip emitter spacing and high extrusion line speeds, that translates to a 2’000 hole per minute requirement.

Knowing where to aim

Part of the challenge in drilling a hole in fast moving target is knowing where to aim. Our patent pending emitter detection system helps us synchronize the movement with laser light precision. Plus, with our auto-tuning algorithm, we zoom-in onto the emitter pool zone quickly and simply. The less practical tuning techniques offered traditionally have been eliminated. You can see the resulting pattern on the monitor.

Ease of operation

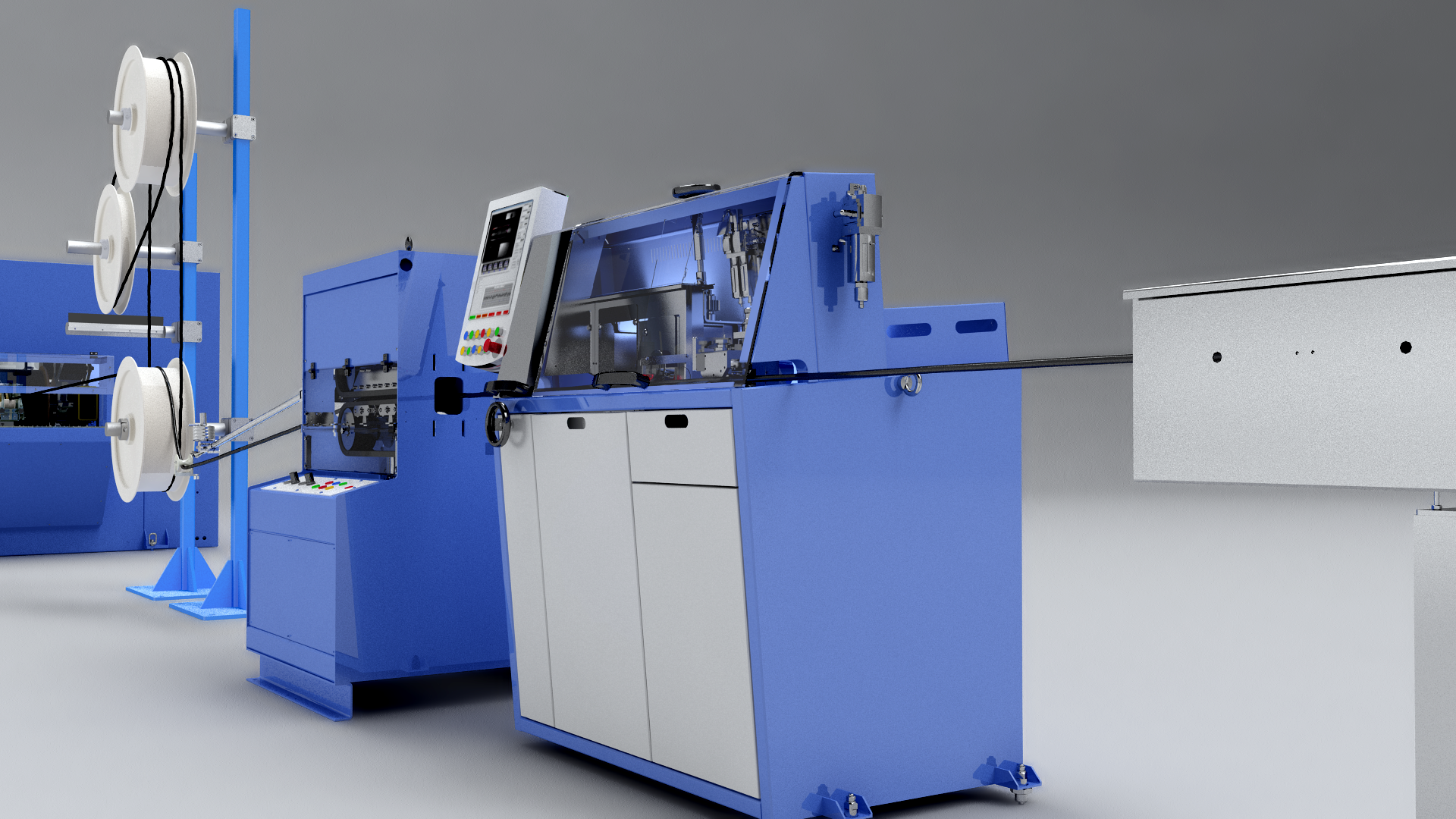

Our leading-edge technology needs little operator intervention. The tube traverses the drilling machine with minimum constraint and deviation. It falls into position automatically on start-up. The drilling cabinet remains closed during operation, while visibility through the protective glass is secured. All adjustments remain safely accessible from outside the cabinet. The goal is to minimize start-up and set-up times in a secure environment.

Indeed, there is more to making holes than meets the eye. Maillefer’s drilling equipment succeeds in simplifying what is in reality a complex operation.

Ernst Geider, Product Manager

ernst.geider@maillefer.net