Cooling product on an extrusion line may appear commonplace. But, the extra attention given to chilling water means being trendy when it comes to performance, quality, and environmental considerations. Indeed, compromised line speed, passable product quality, excess electrical and water consumption are handicaps to maximizing value and to looking good to premium buyers of your product.

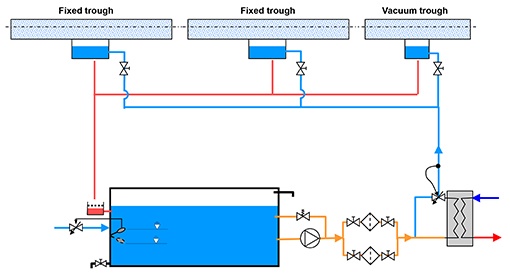

Our closed loop cooling systems are designed to efficiently and properly absorb the thermal energy coming off the extruded product. They are sized according to the configuration of the line and to optimize thermal exchange at the point of use. By opting for a self-regulating closed loop system coupled to our extrusion line, you address the temperature requirements of the process instead of adapting it to an averaged out chilled water supply coming from the factory.

Water flowing through an extrusion line's calibration and water troughs serve to secure product integrity and quality from the hot melt formed in the head. Depending on the process, cooling requirements may be constant or vary as you move downstream along the line. Top production speeds are only possible when sufficient water is available at the right place, at the right temperature and at the right time. The surface aspect for a smooth eye-catching product often depends on it too.

Utilities costs are addressed with a closed loop system. Chilling water only for the volumes needed is economical and environment friendly. Losses due to maintaining the temperature for unneeded volumes, evaporation or purging of waste water are limited. Redundant filters keep water clean and circulating especially during a filter replacement. Separators work to remove particles and avoid clogging. Occasional top-offs are done automatically with access to a fresh water supply.

Closed loop cooling system sized for a customer's PEX pipe application

Getting cool is accessible to all but doing it right is what makes you look good. Maillefer offers closed loop cooling as an option with its Pipe & Tube extrusion lines.

Philippe Giovangrandi

Technical Sales Director, Pipe Solutions

philippe.giovangrandi@maillefer.net

Topics: Performance solutions, Product quality, Production Capacity, Pipe & tube manufacturing

We're actively developing our solutions for medical since announcing features like pre-cut and short lengths one year ago. Now, we've concentrated on ...

Read moreWith its most recent micro-drip irrigation extrusion line, PIL // Explore, Maillefer continues to build-in innovative solutions that improve ease of ...

Read moreWe wanted more speed from our extrusion lines for soft PVC intravenous (IV) tube and we got it. The jump is considerable. It increases production ...

Read more