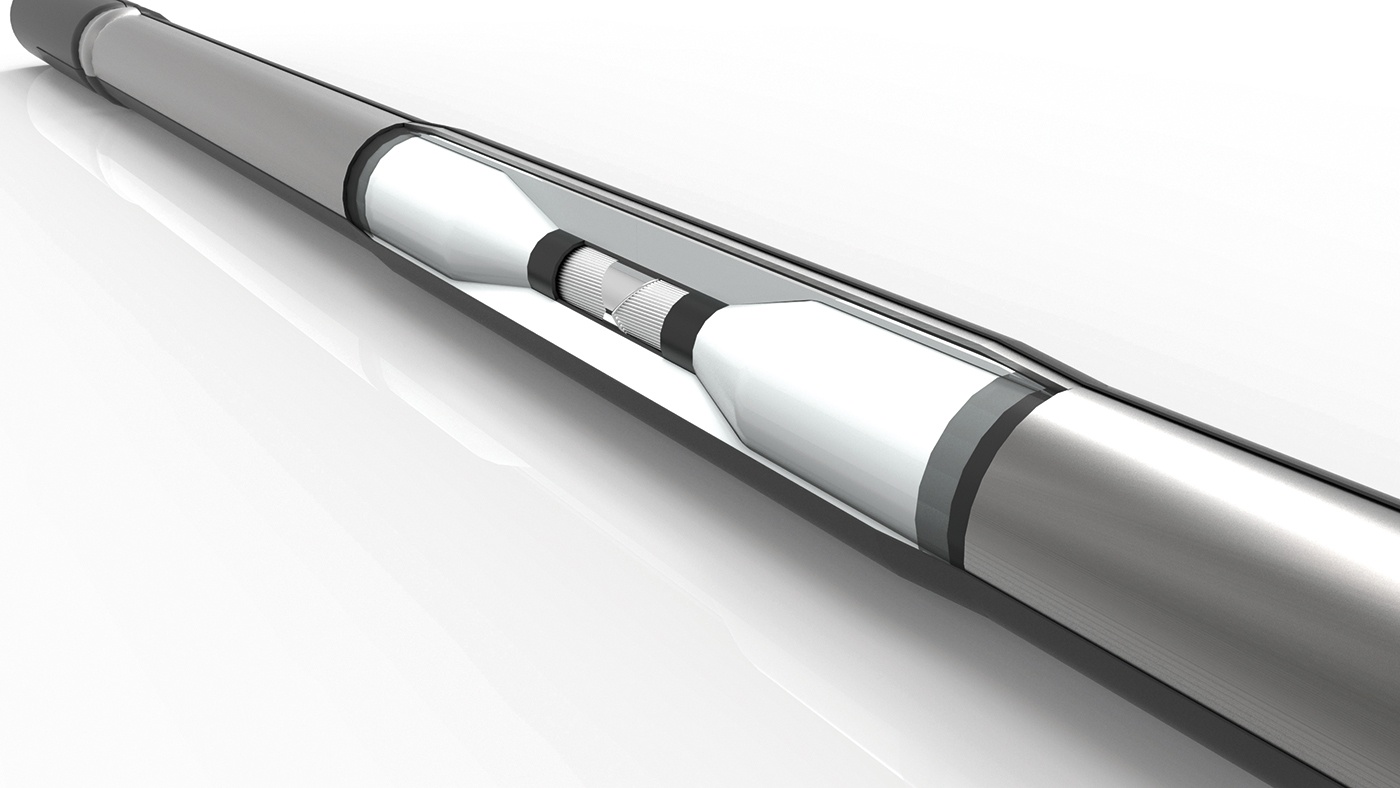

A Cable Technology Package (CTP) is developed especially for High & Extra High Voltage Subsea Cable (AC) Flexible Vulcanized Joints (FVJ). The CTP was presented at the wire 2018 exhibition.

The concept of Technology Process Management (TPM) aims to include the complexity of technology and quality control (QC) issues in different processes within cable system design and manufacturing. The first CTP based on TPM is purely focusing on the complexity of producing AC XLPE submarine cable factory joints up to 245kV (CTP-FVJ/AC).

The target is to control the whole joint project from start to end, including issues such as certification of welders, jointers, dynamic instructions and calculations for design and manufacturing as well as statistical tools for historical joint data and reporting.

Software for dynamic logic is included, as well as calculation of both vulcanizing and degassing parameters. When starting up new technologies, for example AC XLPE factory joints, the complexity is not solely related to the manufacturing itself, but also other parts, such as:

These conditions will require significant time and effort before they are stabilized. The concept of TPM aims to integrate these parts into one software tool, for example CTP-FVJ/AC.

The initial investment in CTP is covered by what a single failure after cable installation or a few failures during manufacturing would cost.

Timo Mäkelä

Product Manager

timo.makela@maillefer.net

Topics: Uppgrade solutions, Novelties & Launches

Quality control and meeting the product specifications are very important in power cable production. We offer a new method for reliable and error ...

Read moreMaillefer has recently acquired a Cable Checker unit for our new R&D lab. The unit is essentially a microscope connected to a hot oil bath for ...

Read moreCable breakdown can cost you your customer. This is especially true for demanding applications, such as high and extra high voltage underground and ...

Read more