Few major producers occupy the oil & gas pipe niche. They seek innovative extrusion solutions to meet the increasingly stringent requirements in the field.

Few major producers occupy the oil & gas pipe field. It is definitely a niche market. The pipes made are large in diameter and complex. Multiple functional layers, where each layer is subject to particular constraints, characterize the off-shore and on-shore flexibles. Indeed, these pipes are exposed to harsh and demanding conditions.

Maillefer provides equipment for installations that are typically tailor made. Known for its extrusion groups, we have established ourselves in the domain for more than a quarter century. Customers get our support from the start, with innovative technical solutions to meet the increasingly stringent requirements in the field.

Modeling tons of flow

With the assistance of our Engineering and R&D resources, you gain access to consulting services and proactive support in the development of uniquely designed parts, particularly in the area of extrusion. The focus of analysis can range from a single distributor to a complete extrusion head, as illustrated by our series of Very Large CrossHeads (VLCH). These heads can reach die diameters up to 650 mm or more, and weigh nearly six metric tons. Benefiting from a strong knowledge of materials, our specialists are capable of providing you with in-depth 3D analyses using finite element modeling (FEM) methods

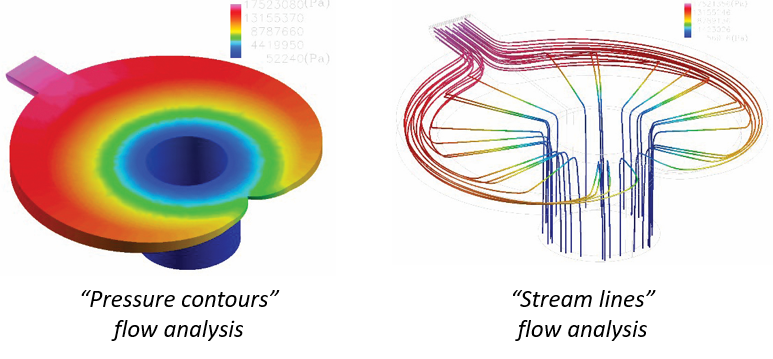

The graphic below shows an example of FEM analysis on a radial distributor. The design aim is to optimize the circumferential distribution of the molten polymer so as to obtain a layer of constant and controlled thickness.

Reaching for an ideal

The extrusion heads developed by Maillefer are designed to transform complicated engineering polymers that have varied and critical properties. In order to optimize the technical characteristics and process capability offered by these heads, we first perform a theoretical analysis. It is subsequently validated experimentally in partnership with our clients.

The development process during a project involves much communication and interaction between involved parties. You, as client, are at its heart. We want to achieve complete satisfaction by reaching for an ideal. The result is to make you stand out with superior product, one which strengthens your market position in a complex and specialized field of activity.

Support from the source

Thanks to our close relationship with material suppliers, Maillefer is able to make the link benefit pipe manufacturers. You get the best possible products, through the optimized and controlled processing of technical polymers, with support from the source. Maillefer recognizes each project for its own specificities. In return, customers get to benefit from personalized solutions.

Philippe Giovangrandi, Technology Director

philippe.giovangrandi@maillefer.net

Topics: R&D, Innovation, Pipe & tube manufacturing, Flexible tubing, crosshead, polymers, oil&gas

Polyurethane (PUR or PU) is an extremely resistant polymer used in special applications like compressed air tubes, oil and fuel tubes, oxygen & ...

Read moreLegend Valve & Fitting, Inc. has been in the business of providing plumbing and hydronic systems for over 30 years. The bulk of their business ...

Read moreOne of the many challenges of producing medical tubing is the use of flexible materials. Improve diameter stability and concentricity coming from ...

Read more