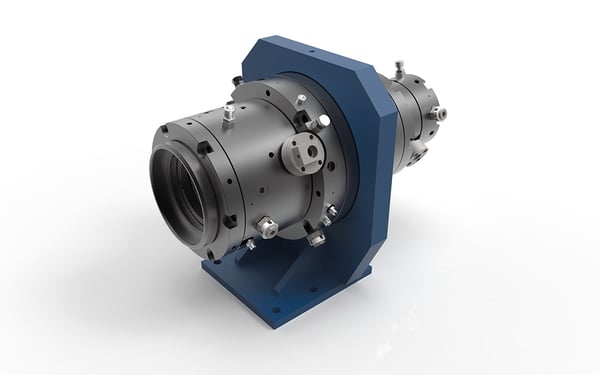

The THC100/180LR crosshead is here. Its optimized Bi-Flow distributors enable accurate wall thickness, centricity and roundness of the cable.

A perfect solution for high and extra high voltage cable production. Optimized Bi-Flow distributors enable accurate wall thickness, centricity and roundness of the cable. Short residence times, streamlined flow channels and efficient water tempering allows long production lengths and smooth layer surfaces. Centering of all layers can be adjusted independently. Conical flow pieces are made of nitrided steel to ensure continuity in production for many years.

Petri Vetterstrand

Chief Engineer, Extrusion

petri.vetterstrand@maillefer.net

Topics: Wire & cable manufacturing, Innovation

Quality control and meeting the product specifications are very important in power cable production. We offer a new method for reliable and error ...

Read moreOur new three-layer crosshead THX 100/180 LR is now available for high and extra high voltage cable insulations. Optimized bi-flow distributors ...

Read moreAt the Inernational Cable and Connectivity Symposium 2016 this October, we presented new limits for ultra-high speed buffering. The global demand for ...

Read more