An investment approval is needed before going forward with your project. A well thought out business plan is backed-up by results coming from our Plant Definition Study. It is the initial step for reaching the key decision.

The target of the study is to find the most feasible and techno-economic realization that will meet the production requirements within a predefined set of constraints. The goals are mutually specified. Also, foreseeable scenarios for future capacity expansions are considered.

The process and related equipment are evaluated in detail. A clear solution is proposed that includes:

Within a PDS, Maillefer also proposes a virtual model of the future plant with computer simulations. It provides the quantitative data about the project. Simulation is effective for optimizing the production processes and internal logistics. Reveal bottlenecks, fine-tune product mix and production planning, optimize work-in-progress, and balance buffers between process steps. Validate your ideas beforehand. Simulation results can argue in favor of a project's realization.

Getting the green light is a significant achievement, but what next? You need to communicate specifications to the civil engineers and architects concerned by the construction. Time and resources are of the essence. That's when the Plant Engineering steps in.

Plant Engineering documents are a necessity for an effective implementation of your project. Our service supplies the comprehensive data needed for the building design, the utility network as well as plans for production machinery foundations and other relevant constructions. The compilation addresses several topics, some key ones follow below.

Detail level layout design - A detailed drawing of machines and equipment locations shown in detail and describing different functions and processes with interfaces to civil design. In practice this part is done in parallel with the civil design of the factory building, for a constant exchange of information.

Building design tasks - Effective installation, use and maintenance of production machinery with respective material flow gives the construction team the limits to be followed in the design of the building.

Process utility network data - The process utility network is a vital element of a functioning plant. Proper planning early enough is essential to ensure the availability of all required utilities, like electricity, water, air, process gases and telecoms. The data for the utilities quality and consumption is gathered and processed and then supplied for HVAC/Civil design of the premises

Line loads and foundations documentation - The line loads and foundations documentation provide information to plan and make preparations of the building. This contributes to effective installation of the lines.

Sustainability - Defines the basic guidelines for establishing the health, safety and environmental protection procedures of the cable manufacturing plant. They include operational concerns for the personnel, processing of gases, liquids and materials, handling of scrap and wastes generated, as well as considering environmental impact. The guidelines serve as a general basis to which local legislation is then integrated.

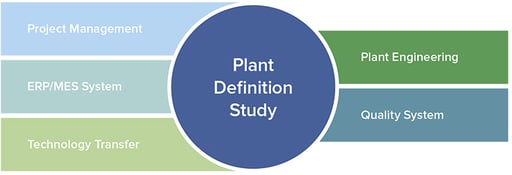

By calling on a PDS and PE from Maillefer, you help ensure that your project will be successful. In addition to these two essential phases, we can further assist by managing the project, calling in consultants for the ERP/MES system, organizing a technology transfer, and setting up quality protocols and qualifications. Our Factory System solutions offers you the support to make your promising ideas come true.

Juha Hiltunen

Project Director

juha.hiltunen@maillefer.net

Tapani Savolainen

Plant Definition Consultant

tapani.savolainen@maillefer.net

Topics: Solutions, Maillefer, Performance, Production Capacity, Wire & cable manufacturing

Where can you see upcoming opportunities in your market? Would it involve the set-up of a new cable factory? Or maybe it requires an expansion of ...

Read moreDo you know how to make the most out of your production? With the experience of over 4,000 line deliveries, we have now launched a full stack of ...

Read moreDo you know your production line capability? Or the hidden performances which could easily be utilized from your existing capacity? Overall Equipment ...

Read more