Joint connections in any cable system are crucial. Depending on the kind of application and the resulting lengths produced, different joint types are required.

Land cables typically need several premanufactured joints, ready to be installed in the field. The installation length of land cables is limited by the weight of the cable and transport constraints. Cable lengths on land tend to be shorter than in submarine installations.

For submarine cables different factors limit length. They are given by the ability to extrude a quality cable continuously over long periods, as well as the testing and storage capacities. Such factors, under control of the manufacturing site, finally determine installation lengths. Therefore, it is common to install joints at the cable factory itself, using flexible joints (or factory joints).

Because joints are a crucial part of cable constructions, their installation, and insulation integrity must be ensured. Design requirements and quality assurance for extruded high voltage AC cables and joints are well established and governed by IEC standards and CIGRE recommendations. For extruded High-voltage DC cable systems, the story is different. Extruded HVDC cables are relatively new technology, with only 20 years of service experience in comparison with the approximately 100 years for paper-oil cable systems. This puts additional demands on design, quality assurance as well as development testing for extruded HVDC cables systems.

The main difference between AC and DC cable applications is the material parameter governing the electric field distribution in the insulation system. Permittivity controls the electric field for AC, whereas conductivity controls the field for DC. Physical cleanliness (i.e. the number and size of particles in the insulation system) is as important for HVAC as it is for HVDC. A particle will increase the local electric field in the vicinity. Chemical cleanliness, which encompasses peroxide decomposition products, antioxidants, and other additives intended to improve processing, becomes important for DC applications. Any addition tends to augment the conductivity of the insulation.

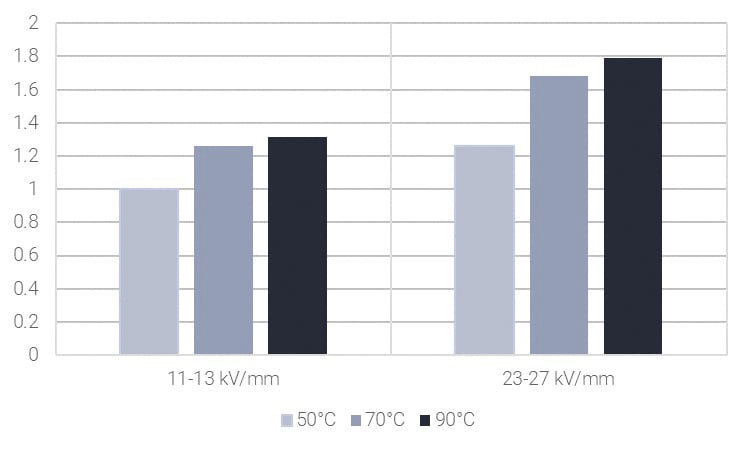

Characterizing both materials and processes with respect to influence on the conductivity is paramount for the development of HVDC cable systems. For instance, the ability to measure the amount of peroxide decomposition products with HPLC (High Performance Liquid Chromatography) as a result of curing a particular material and linking this to measurements of the conductivity is a powerful skill. It provides information both on the insulation material used for the joint as well as the curing procedures and the need for degassing that follows.

Fig. Relative conductivity in an extruded cable

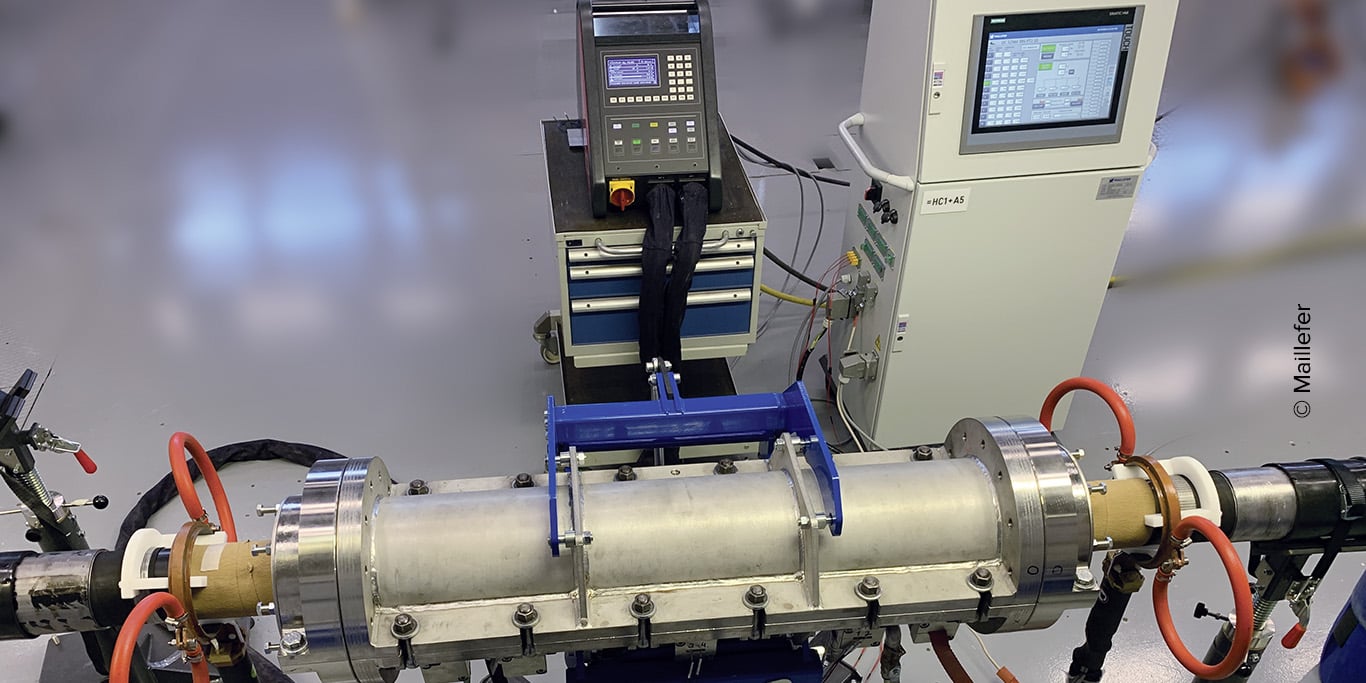

Maillefer has developed multiple technology packages for extruded XLPE insulated HVAC and HVDC subsea cable factory joints over the years. We offer factory joint technology packages for different voltage ranges, starting from 66kV AC inter-array cables to 245kV AC export cables up to 420kV AC interconnection cables. We have now launched similar packages also for 320kV DC and 525kV DC cables.

We provide comprehensive factory joint technology packages that consist of:

Timo Mäkelä

Process Specialist

timo.makela@maillefer.net

Topics: Solutions, Maillefer, Wire & cable manufacturing

Astonishing Curing Calculation for Flexible Factory Joints Flexible vulcanized joints (FVJ) also known as flexible factory joints are typically used ...

Read moreFew publications exist and are readily available which treat factory joints in the area of Extra High Voltage DC cable. This paper sheds some light ...

Read moreSince the early times of extruded high voltage subsea XLPE insulated cables, it has been mandatory to develop reliable in-house solutions for ...

Read more