How is digitalization shaping the future of production in the wire, cable and pipe industry? Maillefer Smart Factory is opening up a great platform of opportunities for modern manufacturing.

The technologies of digitalization offer almost endless opportunities for today’s technology industries. We hear that digitalization will shape the future of production, naturally also in the wire, cable and pipe industry. Are we on a path to full automation of plants?

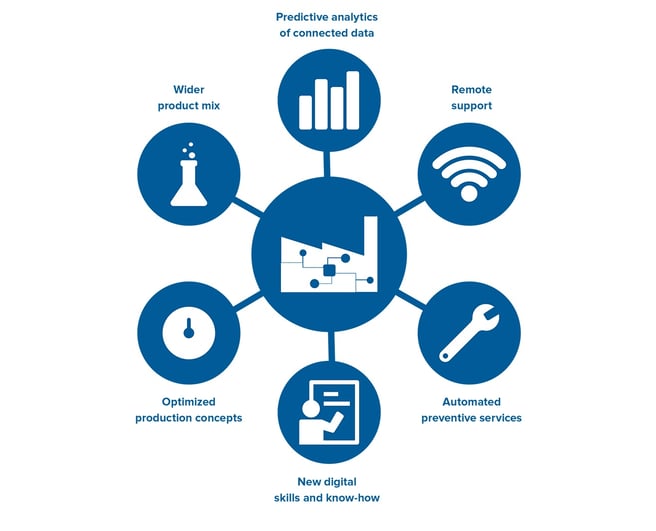

For Maillefer, a company driving revolutionary innovation in process technology, digitalization is a great platform for opportunities. The Maillefer Smart Factory is here to present these opportunities.

The Maillefer Smart Factory is an umbrella of solutions, with the utilization of data as the common factor. What we strive for is measuring, collecting and processing data, and linking it to our process know-how and produce intelligence. In the end, this will optimize the process and create added value.

Our ambition is to develop factory solution that optimize the end product quality and productivity simultaneously. A Smart Factory is more resource efficient and utilizes real-time production optimization concepts. Connecting online process data with online process controls and with factory MES and ERP systems brings real-time transparency in production management.

Using simulation capabilities that are built on real input data and a high level of process understanding enables upfront visibility in total manufacturing efficiency. It also adds flexibility in the production mix, and makes market entries and reactiveness more powerful.

Maillefer Smart Factory solutions focus on developing measurement technology and collection of key process data for the optimization of product quality and process efficiency. Our new Topography Scanner device is a great example of such a solution.

In the future, we foresee a more closed loop of automated process optimization, which will make the production of high-quality end products more efficient. Quicker, direct response will be optimized overall, but visibility for operators and management of production performance will also improve. Remote controls and remote links, already available, will enable online trouble shooting, support, and training.

Maillefer introduces preventive, automated maintenance solutions, with online service links available at demand. In the future, online process and component controls will proactively provide information of the maintenance activities required.

Our factory design capability has enabled us to build a virtual 3D manufacturing world. Green field factories, or factory extensions, can be built in 3D simulation, reflecting a real and exact manufacturing setup and running a predefined production volume and mix. Required process machinery, optimal factory floor logistics, work force, among others can be predetermined, or planned changes in the production can be tested. This digital solution opens completely new windows for the optimization of manufacturing in large scale.

In addition to all this, the Maillefer Smart Factory solution offers a number of know-how solutions connected to new component or value upgrade products. Several OEE tools and new digitalized sub process optimization programs are introduced.

The Maillefer Smart Factory offering is a natural part of our consultation products.

Mikko Lahti

Director, R&D

mikko.lahti@maillefer.net

Topics: Novelties & Launches

We are continuously working together also with material suppliers to improve our products and NCC curing calculation software is not an exception. ...

Read moreThe productivity of an optical cable manufacturing line can be improved significantly by increasing line speed. Our buffering process has set totally ...

Read moreThis new compact take-up is designed especially for small fiber optic jacketing lines. The machine is optimized for light weight and flexible ...

Read more