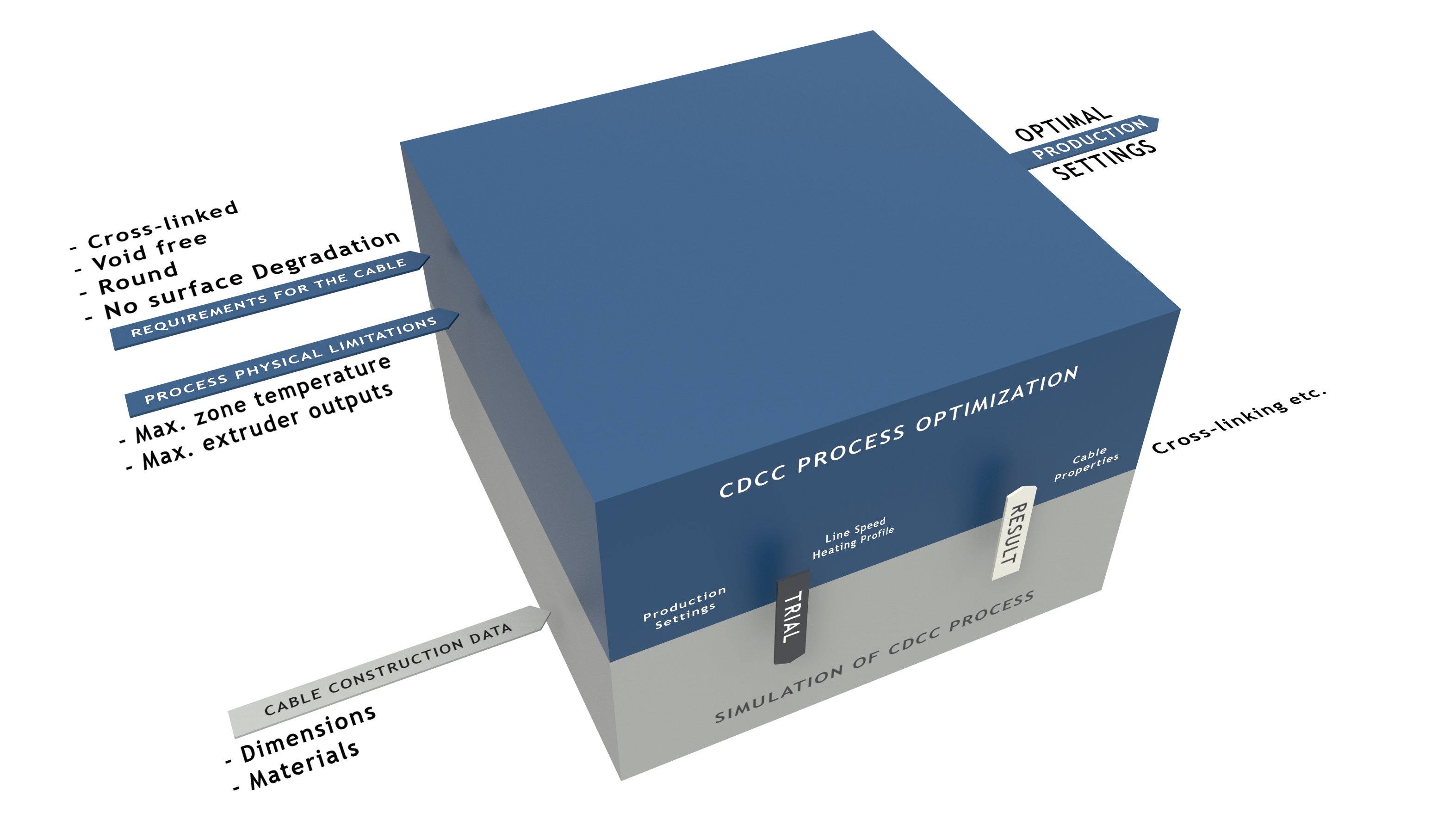

We are continuously working together also with material suppliers to improve our products and NCC curing calculation software is not an exception. The latest update in NCC adds functionality to support material specific curing profile optimization. Now we can create constraints or optimization window for parameters that are not typically used for curing profile calculation.

The first module has been developed for HVDC insulation material and helps our customers to increase productivity without sacrificing quality of the insulated core. Extensive experiment data has been generated at our Pilot Vertical Line and complemented with data from customer CV lines. Such data driven development makes it possible to fine tune the curing calculation and optimization parameters to achieve even last percentages of productivity improvement.

Janne Harjuhahto,

R&D Engineer

Topics: Production Capacity

New function in the Curing Calculation Program NCC for calculating optimum degassing times.

Read moreMaillefer's core know-how in power cable production lines is linked to the curing calculation program (NCC). NCC allows its users to optimize current ...

Read moreOur NCC curing calculation tool migrates to an easily accessible web-based software. Optimize production speeds and share simulations between sites ...

Read more