Several criteria condition the type of micro-drip pipe to produce, like market situation, its readiness to adopt a modern irrigation technique, crop requirements and local climate, available raw materials and dripper designs, investment budget, and the performance targets are some of the points to consider.

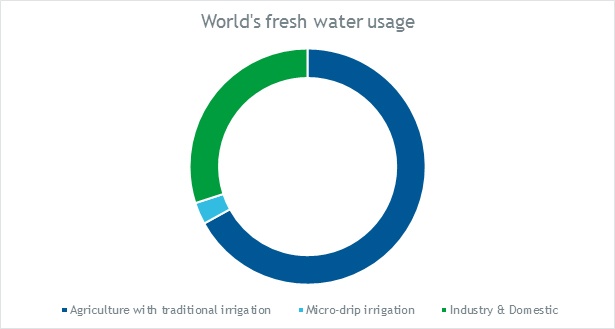

The increasing world population and the limited availability of fresh water is posing more questions on how water can be better used in agriculture. Studies show that about 70% of our precious resource withdrawn goes towards agriculture and of that huge part only 3% finds its way into water smart micro-irrigation (source UN's Food and Agriculture Organization; www.fao.org). Though relatively small, that portion holds much promise for our food supply and our planet.

Despite the overwhelming benefit, farmers and growers hesitate when moving from less effective irrigation methods to more economical micro-drip. They include initial entry costs, the expertise to install and maintain, the short life of plastic components, and lack of familiarity. The encouragement and support coming from local authorities and industry players are key to bringing about the needed change.

The application and climate where the pipe is installed determines its construction. A heavy wall pipe with carbon black supports rough handling and long sun exposure. It is seen for example in orchards where the pipe will stay in place over multiple seasons. On the other hand, a disposable product with a thin-wall may be more cost effective when growing a seasonal crop with a single harvest.

For a commodity item like pipe laterals, the raw material costs and local availability structure the price of finished product. Thin walls, tight tolerances, and multi-layer constructions employing regrind represent some strategies used to increase sales margins. Whereas, emitter quality and precision spacing can help justify a price premium.

In anticipation, a growing number of machine suppliers provide complete or partial solutions, with varying performance and quality. For those looking to acquire production capacity, it is clearly a buyers' market. But the difficulty comes in choosing the right partner.

We respond to the variety of requirements with several models of manufacturing systems, configured for your emitter type, flat or round laterals, and thin or heavy walls. Plus, our /Enter //Extend and ///Explore levels help you ideally position yourself along the price/performance scale. Maillefer's irrigation portfolio is single sourced and complete, from dripper feeding, to extrusion to winding. We make sure that our solutions create the favorable conditions that help you achieve your business goals and succeed in your specific market.

Ernst Geider

Technical Sales Director, Micro-Drip Irrigation Solutions

ernst.geider@maillefer.net

Topics: Product quality, Production Capacity, Production cost, Pipe & tube manufacturing

What a challenge! How to keep micro-drip irrigation drippers all lined-up perfectly and in pace with our high extrusion line speeds? Maintaining an ...

Read moreUsers of micro-drip irrigation for seasonal crops look towards the most economical thin wall laterals available. Two types fall into this category – ...

Read more