Many parameters must be considered when one calculates the cost price for a meter of micro-drip irrigation tube. As an equipment provider, Maillefer looks at how economically its lines operate in a production environment.

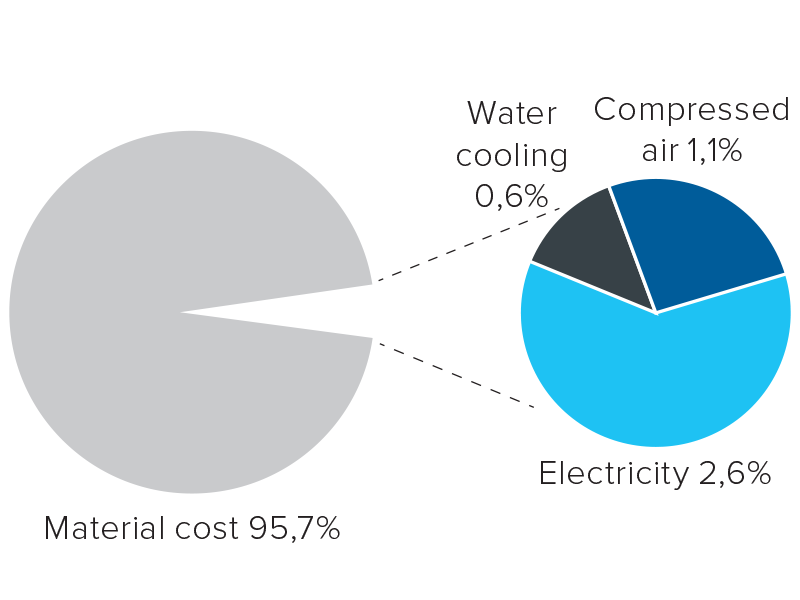

We've measured electrical, water and air consumption while producing both thin and heavy wall irrigation laterals in our R&D Center. Utility costs represent a modest 5% in comparison to raw material costs. Electrical consumption accounts for at least 2/3 of those utility costs. This is largely due to the main extruder itself. Efficient extruder designs and modern AC drive technology are available to minimize the energy costs. However, we wanted to also study the costs coming from cooling water and compressed air systems.

A first analysis was done by extruding a DN16 thin-wall tube with a thickness of 0.15 mm. The graph above shows utility costs in comparison to material costs and include breakdowns by utility types. In this case, water and air take up more than 1/3 of the 4.3% in utility costs. For the purpose of simplification, we calculated material costs without the emitters since their contribution depends significantly on their spacing and the resulting numbers per meter.

We used a similar approach in a second analysis for a heavy wall tube. While more cooling water per meter of pipe was needed, the thicker wall required about the same amount of cooling water per weight of material, but noticeably less compressed air.

Trials lead to new developments and improvements, such as:

We continue putting our equipment to the test. In a highly cost-conscious business environment, Maillefer recognizes its role in providing you equipment that operates economically.

Ernst Geider

Technical Sales Director, Micro-Drip Irrigation Solutions

ernst.geider@maillefer.net

Yves Zweifel

R&D Manager and Process Leader, Irrigation

yves.zweifel@maillefer.net

Topics: Production cost, Pipe & tube manufacturing

Count up to 90% of volume for the main layer in a triple layer tube construction. That is the proportion of material employed in comparison to the ...

Read moreAre you looking for more reliable high and extra high voltage power cable systems with better joints, terminations and lower material costs?

Read moreAre you interested in reducing material costs and improving cable quality in your CV-line production?

Read more