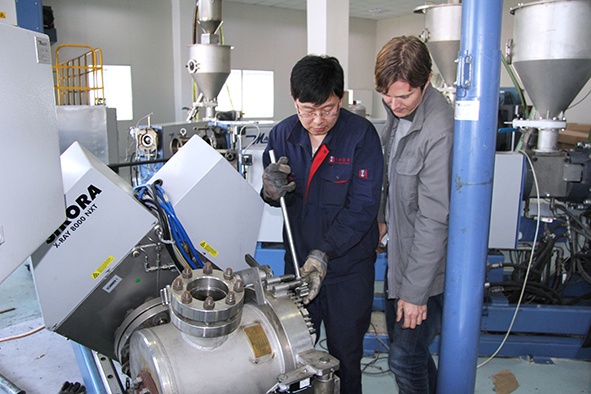

Dalian Jinzhou Cable’s first rubber cable production line from Maillefer is up and running. After a busy year of 2013 with numerous 10 kV cable deliveries, the new line opens doors to making cables for the building, wind park, ship, mining, and rolling stock industry as well as for heavy industry.

Being one of the biggest wire and cable manufacturers in Northern China, finding a versatile solution covering different application and product type needs is a must. “Maillefer was not selected lightly. We were listening to our customers’ feedback very carefully. The possibility to manufacture both rubber and XLPE cables, the European origin of equipment and the level of automation were all part of the selection criteria. In addition Maillefer offered us (the) curing calculation program NSS, which has been an extremely useful tool also for production planning,” describes Mr. Li Yunhai, Vice General Manager.

High flexibility in production processes and cable materials is one of the top customer values for Dalian Jinzhou Cable. High cable quality and secured lead times are possible, when production processes are stable. “Our cooperation has given us not only new technology, but also more process and material knowledge to guide our customers to profitable choices”, continues Mr. Li.

Dalian Jinzhou Cable Co., Ltd. chose Maillefer for its high speed rubber insulation and sheathing line with Super Steam technology, also called Super Cure in Chinese. The total control of production was particularly emphasized to secure the rubber cable quality. Automated functions, process data reporting, the NSS calculation program and independence from steam pressure create the production conditions that are favorable to successful production of even the most sensitive cable constructions.

The right capacity and lower production costs are also key issues in China. Mr. Li continues, “The Super Steam process with low steam pressure multiplies our capacity in rubber cables. In medium voltage XLPE cables we can reach a 10% increase.” The new line produces very little start-up and shutdown scrap. Savings come from multiple sources – optimized usage of extruded materials, minimized scrap costs, low steam and energy consumption.

In total, overall efficiency has increased up to 60%, which is an excellent result. “We can definitely recommend Maillefer as a business partner for anyone appreciating adaptive technologies, process know-how and true customer support”, Mr. Li sums up.

Dalian Jinzhou Cable Co., Ltd.

Vesa Koskivuo

Product Manager, Rubber Cable Solutions

Topics: Product quality, Production Capacity, Production cost, References, Wire & cable manufacturing

Recently, Maillefer installed and commissioned a first series of Topography Scanners on customers’ power cable lines. Thanks to the support of Nexans ...

Read morewire Russia is the industry’s most important trade fair in the region with over 200 exhibitors from more than 25 countries and over 10,000 visitors ...

Read moreThe continued increase in electronic applications in aviation and aerospace industry in addition to the growing demand from aircraft manufactures for ...

Read more