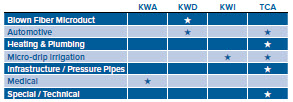

Each pipe or tube application has its specificities matched to an ideal winding system. Maillefer proposes a palette of different of coilers / reelers best suited for the job.

Each pipe or tube application has its specificities matched to an ideal winding system. Dual winding, safe fully automated transfers, and ergonomic handling all play their roles in ensuring the quality of finished product.

The KWA series is designed especially for coiling medical tube, where maintaining product integrity is an important measure of final quality. Line speed in relation to rotational speed is synchronized with traversing and switchback in order to result in perfect lays. It achieves the required quality for smooth and clean finished coils, without gaps, overlaps and tube deformation.

For blown fiber micro-duct and similar technical tubes with diameters ranging from 3.5 to 16 mm, you can chose the KWD in a 1000 or 1250 version. The larger one accepts reels having a diameter of 1250 mm and a full weight of up to 300 kg, perfect when trying to get long lengths for limited micro-duct joints or junctions out in the field.

The KWI is tailored for conditioning micro-drip irrigation laterals onto carboard reels. Plus, there are varying constraints, such as short lengths, cutting and transfers, heavy or thin walls, flat, etc. The KWI models are versatile and well suited for conditioning product that is directly bound for irrigation specialists or the week-end gardener.

The TCA model is the most versatile of our coilers. It covers several applications and offers the most features and options. We apply several cutting and clamping technics to minimize transfer cycle times. Dancers are available for adapting to production speeds and to optimize winding tension. The high-capacity TCA 1300 has turrets for large coils of up to 800 mm wide, an overall diameter of 1300 mm and weighing up to 150 kg.

With the help of an accumulator, intermediate coil strapping with the TCA is possible. It essentially allows you to bind an inner coil within a larger one, which may be an efficient solution for downstream processes. Here, the line continues to run at full speed during the strapping cycle while the accumulator acts as a buffer. The TCA has an option for easy adjustment of coil widths and diameters either manually or through a power drive.

The TCA responds well to various unloading concepts, from a classic hydraulic lift for one line to tailor-made robot handling for a group of lines integrated into a production management system. Together with our partner, BMGroup, we have solutions for ensuring smooth and efficient flow of product between processes and towards delivery.

Dual winding, safe fully automated transfers, and ergonomic handling all play their roles in ensuring the quality of finished coils or reels. Maillefer’s coilers and reelers for tube & pipe applications are available as individual components ready to upgrade into an existing extrusion line or come fully integrated into complete production systems.

KWA Features

KWD Features

KWI Features

TCA Features

Services Sales Manager

raul.perez@maillefer.net

Topics: Performance solutions, Uppgrade solutions, Solutions, Maillefer Services, Maillefer, Performance, Production Capacity, Upgrade Solutions, Value Corner, Novelties & Launches, Extrusion, Innovation, Pipe & tube manufacturing

There is a cutter for each Pipe & Tube application that Maillefer delivers. Cutting design, safe access, and ergonomic handling all play their ...

Read moreWeb-enabled NCC makes production and investment planning even more accessible. Its calculation engine helps determine production speeds on all types ...

Read moreMaillefer has logged more than 200% more in CV line orders for China in comparison to prior years. The 500th CV line milestone was past not so long ...

Read more