Maillefer announces features for its PML extrusion lines for the production of soft PVC medical intravenous (IV) tube. Thanks to cooperation with the world’s leading medical device manufacturers, innovations on tube surface finish and for conditioning have been brought about. Advantages are increased production speed and product optimization that are carried over to the manufacturing processes located downstream.

A smooth and glossy IV tube surface may be appealing but it has the undesirable effect of surface tackiness, which is noticeable when conditioned on coils. The winding and later unwinding operations are slowed as a result. In order to eliminate adherence, Maillefer has a feature in its extrusion group that adds a textured finish to the tube's surface. With it, overall rates of production are improved.

A second improvement is destined for the assembly process downstream. Up until recently, the conditioning possibilities that were available from extrusion are either a full length coil, or individual cut lengths. A coiler is employed for the former, while an integrated cutting machine is used for the later. In the case of coils, IV tube must be unwound and cut into individual lengths prior to assembly of medical devices.

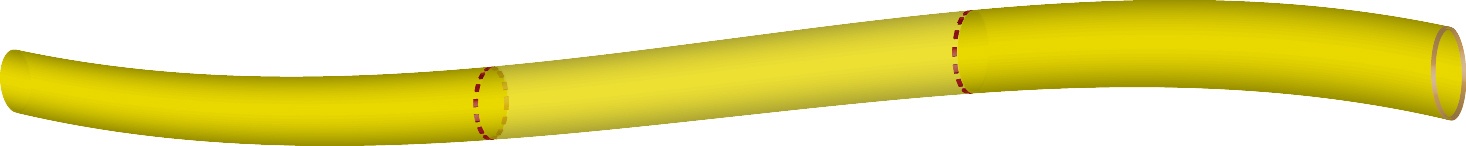

The innovation proposed is to deliver easy to handle coil that contains already pre-cut IV tube. Here, pre-cut tube is prepared on the extrusion line, while maintaining a tractable tube for coiling. The tube delivered downstream on coils is now easily separable for later assembly.

Maillefer’s PML 032 line is geared for a speed of 300 m/min. Manufacturers’ typical tube constructions are produced at 200 to 240 m/min. The line operates at constant speeds, even during coil transfers. Available control features include process monitoring, data logging, event alarms, recipe storage, scheduler, report generator and video monitoring. The entire line is designed and built to the strict requirements of the medical device industry.

Philippe Giovangrandi

Technical Sales Director, Pipe Solutions

philippe.giovangrandi@maillefer.net

Topics: Performance solutions, Production Capacity, Novelties & Launches, Innovation, Pipe & tube manufacturing

Plastics have gained a significant place in today's automotive industry. There is a variety of multi-layer tube & pipe constructions, from ...

Read moreOne of the many challenges in the medical device industry is the production of plastic PVC or PU tube. Two optimization methods for flexible tubing ...

Read moreMore and more manufacturers around the world have arrived on the scene and are producing micro-duct for blown fiber. Their needs for increased ...

Read more