One of the many challenges in the medical device industry is the production of plastic PVC or PU tube. Two optimization methods for flexible tubing are available on medical extrusion lines.

One of the many challenges encountered in the medical device industry is the production of plastic tube employing flexible materials such as PVC or polyurethane (PU). The dimensional characteristics and mechanical properties required for these tubes can be quite demanding, meaning that specific know-how and equipment are needed. Two optimization methods for flexible tubing are available on Maillefer extrusion lines.

Improving stability

For medical lines producing intravenous (IV) tubing or tubing for peristaltic pumps, Maillefer mainly proposes two extruder models from the MXC series. The MXC 60-30D and the MXC 80-30D are proven machines designed with medical tube extrusion applications in mind.

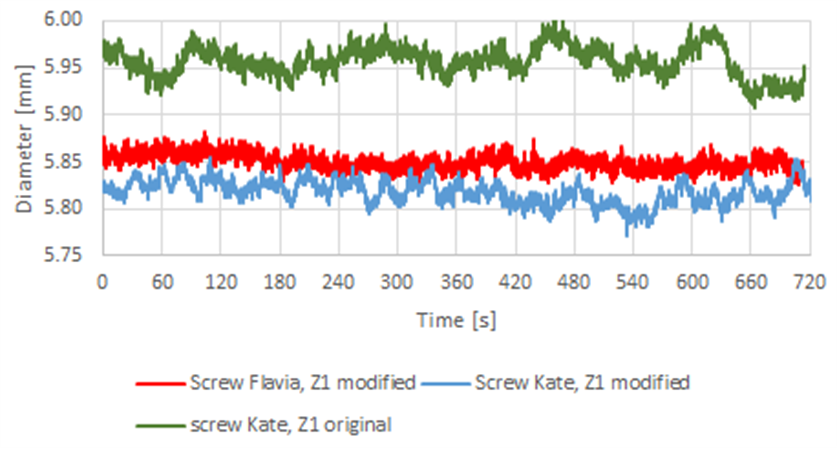

During our proving trials, we focused on improving the diameter stability given by the extrusion group without sacrificing overall line performance. The new machines were equipped with a newly designed screw developed specifically for soft materials, as well as with a precise extruder temperature control system. These two innovations allowed us to guarantee better dimensional stability of the tube as well as improve its mechanical properties.

The innovative screw has a well calculated geometry which improves the stability of the extruder flow. This has a direct effect on the diameter stability. In addition, the shear rate is noticeably reduced.

The graph above shows an example of the diameter stability obtained on a 5.9 mm PVC pipe base.

- Green = standard extruder

- Blue = extruder with new temperature control system

- Red = extruder with new temperature control system and new screw.

These screw and temperature control improvements were brought to light on the MXC generation of extruders, proven in medical manufacturing environments. The two optimization methods for flexible tubing are now proposed for complete medical extrusion lines. They are also available as a Value Package for existing machines.

Philippe Giovangrandi,

Technology Director

philippe.giovangrandi@maillefer.net