There is a cutter for each Pipe & Tube application that Maillefer delivers. Cutting design, safe access, and ergonomic handling all play their roles in ensuring the quality of finished product. Maillefer proposes a choice of different of cutters best suited for the job.

SCB robustness for multilayer tube

The SCB rotating saw is designed especially for cutting rigid multilayer pipe into manageable bars or coils. It is particularly suited for heating & plumbing pipe with an aluminum layer construction, yet also handles gas & water HDPE pipes. Here, maintaining product integrity is an important measure of final quality. The cutting frequency in relation to production speed provides a sizeable window for cross sections up to 75 mm. The accent is placed on safety thanks to the SCB’s protective guards and frame.

Versatile CMB for nearly every application

The CMB 16 and CMB 32 are specially designed to cut flexible and rigid pipes & tubes. Its rotating blade allows a high-speed cut with an accurate cutting length. The cut length accuracy reaches +/- 1 mm according to the product. Two versions are available – the CMB 16 for a max. diameter up to 16 mm and the CMB 32 for a max. diameter up to 32 mm. The CMB 16 is mainly for the medical and automotive market, while the CMB 32 covers applications such as microduct, heating & plumbing, automotive, irrigation and other special constructions.

MPC has a medical specialization

The MPC 14 combines both the pulling and cutting operations into one component, all in one compact frame. The small footprint allows it to easily be integrated into an existing line. This puller / cutter is ideal for medical extrusion lines producing small diameter flexible tubes. Equipped with a rotating high-speed blade, it cuts tube with a high degree of accuracy and precision. Depending on the tube produced and its use, desired cut lengths vary from very short sections (e.g. 20 mm) to longer ones (e.g. 4000 mm). In addition, a straight-through feature allows the cutting head to be disengaged when operating a coiler / reeler that is positioned downstream.

The knife blades are easily accessible for replacement or maintenance. All control functions are centralized on the front panel for easy reach. Downstream options include integration with a reception bin for short lengths, a conveying belt adapted for up to two- or four-meter cut lengths, or a coiler / reeler offering nearly limitless lengths.

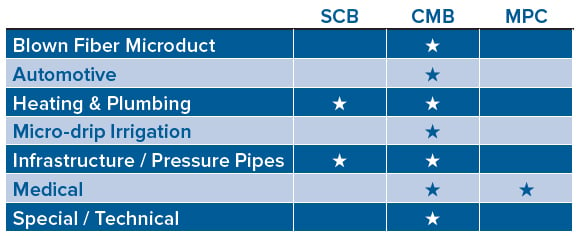

Cutting Solutions by Pipe & Tube Type

The right cutter for the job

Precise cutting, safe operation, and ergonomic handling all play their roles in ensuring the quality of finished pipe & tube. Maillefer’s cutters are available as individual components that easily to link into an existing extrusion line or come fully integrated into complete production systems.

Raul Perez

Service Sales Manager

raul.perez@maillefer.net