Thousands of extrusion lines and components delivered over the decades carry the Maillefer name. Over time they require effective ways to keep running at the highest levels. Here are some of the ways.

Thousands of extrusion lines and components delivered over the decades carry the Maillefer name. Over time they require effective ways to keep running at the highest levels. Components need to either be upgraded to the latest PLC, drives, and motors or may even need an entirely modern component due to higher efficiency or performance requirements. The following gives some ideas for your next and possibly best upgrade action.

Upgrades to secure and boost your production

Basically, any line can benefit from Maillefer’s extensive upgrade opportunities. Depending on the type of needs you have, there will be an available new solution in place and ready for you. A few are described below. More details about the others are available upon request.

PLC, Drive & Motor upgrades

During the years of operation, the standards on the market on the automation side is always changing and developing. Today the old S5 based technology is in need of urgent upgrading. Most of your components such as saws, cutters, coilers and extruders to name a few are in need of upgrades to secure the continuous operation and spare parts availability. Maillefer Services tailor makes the upgrade for you using the latest PLC, new drives, and electrical cabinets. Plus, the switch to a more environmental friendly AC technology is a winner. We supply you with an upgrade package that is either a turnkey sytem put in place by our technicien(s) or as a kit ready to be installed and brought on-line by your own maintenance team.

Renew or upgrade your coiler

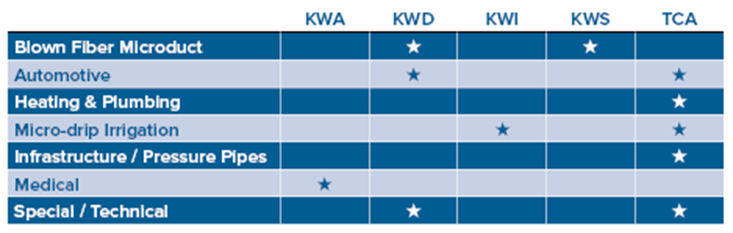

Dual winding, safe fully automated transfers, and ergonomic handling all play their roles in ensuring the quality of finished coils or reels. One example, is the TCA model. It is the most versatile of our coilers and offers several options. Maillefer’s coilers and reelers for tube & pipe applications are available as individual components ready to upgrade into an existing extrusion line or come fully integrated into complete production systems.

Durability at your fingertips

Several options for you as our customers are available for doing structured, planned and targeted line improvements. Keeping your equipment in good shape extends its life cycle. Maillefer Services is happy to provide you guidance and line audits in order for you to plan the next needed actions. Durability for your equipment is within reach. Contact us at Maillefer Services for the next series of improvements on your Pipe & Tube line.

Raul Perez, Services Sales Manager

raul.perez@maillefer.net

Topics: crosshead, Extruder, vacuum, coiler, saw, Automation, cutter

Our roots lie in the extrusion technology, onto which our nearly 20 applications are based on. As an industry innovator, we are constantly seeking ...

Read moreThe latest technology combined with upgrades can decrease material overuse and scrap by almost 10%. It is one way of addressing sustainability in a ...

Read moreAs with any company who needs to reach out to its customers over long distances, Maillefer has a secure and fast way of bringing you remote ...

Read more