What opportunities lie ahead for single layer PEX or multi-layer composite pipes? Within our portfolio of extrusion lines, we include a series of improvements introduced throughout a long history of supplying customers. What were first special options have become standard on newer lines.

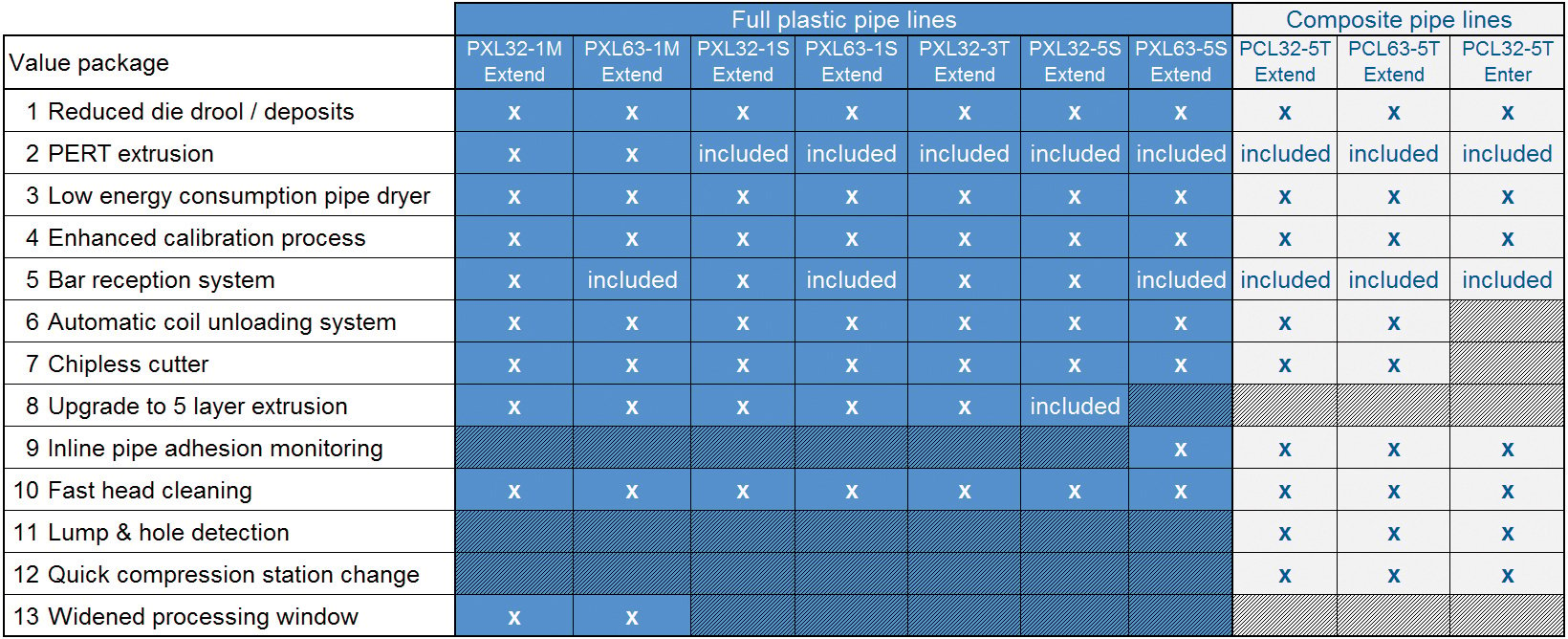

How truly secure is your existing business situation when operating in mature industry that faces multiple challenges? Ensure that you and your production equipment stay in the game. Alongside the Low energy pipe dryer3 and the Inline adhesion monitoring9 value packages first presented in the spring edition of this magazine, we now have selected three more to highlight from the more than a dozen available.

Quick change compression tooling12

Eliminate time-consuming and faulty set-up adjustments of the compacting rollers on the Aluminum forming section of a PCL line. A change in pipe size represents up to two hours saved, thanks to pre-sized fixed position assemblies. Plus, avoid less than perfect adjustments of the rollers, which leads to damage of the Aluminum being compressed. Improved productivity and quality are the result.

The listed upgrades and value packages are available as improvements to your existing equipment. Whether making single or multi-layer, PEX or PE-RT, full plastic or composite pipe, Maillefer provides you with modern subsystems and assemblies that help retain your role as a notable player in today’s Heating & Plumbing industry.

Alain Schiess Christoph Radermacher

H&P Product Manager H&P Product Manager

alain.schiess@maillefer.net christoph.radermacher@maillefer.net