The global airline industry continues to grow very rapidly. Measured by revenue, the industry has doubled over the past decade, according to the International Air Transport Association (IATA). This sets big demands for manufacturing capacity.

On the other hand the number and length of cables used on airplanes is increasingly important due to the vast variety of cables used for data transmission, security, etc. Furthermore the industry’s demand for lighter cables is also increasing which sets certain quality requirements.

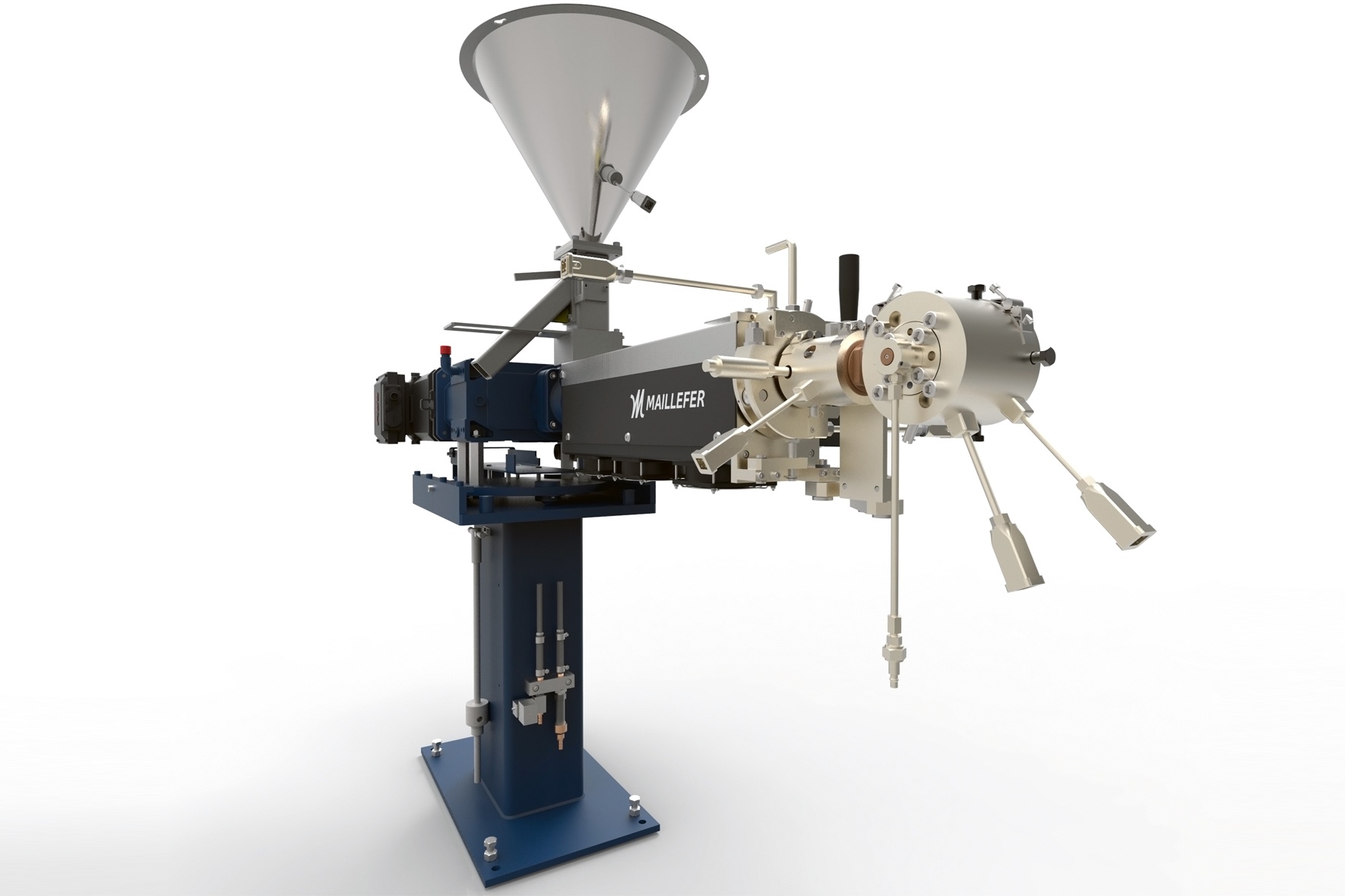

Maillefer insulation line for aviation and aerospace cables

Maillefer insulation line for aviation and aerospace cables

We have answered the market's needs by introducing a new insulation line for aviation and aerospace cables. It is a high performance and quality extrusion line that is specifically designed for producing demanding aviation cables. The new line is optimized for extrusion of X-ETFE extrusion (cross-linked modified ETFE).

- All components are specifically developed for the aviation application. Two extruders, setup in tandem for single or dual layers

- Screw and crosshead design based on precise calculation of specific output (kg/h/rpm)

- Enhanced line control for smooth start-ups with dual layer, and keeping tight diameter and eccentricity tolerances

- Processes fluoropolymers like X-ETFE, FEP, PFA, ETFE and other high temperature materials

- The line is available for customer demonstration and tests on Maillefer premises and it is possible to perform tests with customers’ compounds.

Ramiro Rodriguez

Product Manager

ramiro.rodriguez@maillefer.net