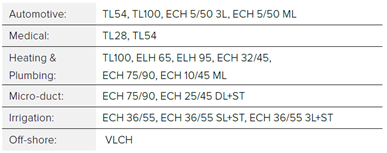

Maillefer has a complete program of extrusion heads which fulfils the needs for pipe & tube manufacturing. Typically proposed in our line offerings, as well as for performance upgrades and component replacements. The TL and ELH longitudinal heads, and the VLCH and ECH crossheads form the four families that cover pipe & tube applications. They respond to a variety of design requirements like single layer or multi-layer, stripe or skin options, co-extrusion or tandem processes, countless adhesives, polymers and elastomers, and special connections and tooling configurations.

A majority of the head designs support multi-layer co-extrusion. Indeed, the ECH models boast high flexibility in layer positioning, superior flow distribution and ergonomic qualities. Take for example the five-layer ECH 5/50. Its indexing feature allows for up to 120 different layer combinations. While the longitudinal TL and ELH families are optimized for single layer or striping extrusion, the much larger VLCH crossheads are dedicated to the off-shore flexible pipe application.

Where manufactures may favor co-extrusion when wanting to unite the polymer flows within one multi-layer head, tandem extrusion configurations offer a valid alternative. Here subsequent layers are added further downstream in a second extrusion step. Specific single layer TL and dual layer ELH and ECH models heads respond nicely in such configurations. We see such setups with certain tubes where polymer viscosities are quite different between layers. A longitudinal TL or ELH head produces the inner tube layer(s) and an ECH one further downstream for the outer layer(s).

Thanks to our program of continuous extrusion head improvements, the ECH series remains a natural choice when requiring high quality multi-layer pipe & tube with maximum material savings. The top-notch design of the crossheads results in exact layer thicknesses and concentricity. With optimized temperature control and state-of the-art material flow distribution, longer production runs are possible with the number of cleaning operations reduced. The goal is minimized down time.

Consider upgrading to a five or even six-layer line, thus opening up the range of pipe & tube constructions to be produced. The ECH crosshead series guarantees reliable production, improved efficiency and gives the possibility to increase product quality.

Calling upon today’s TL, ELH, VLCH and ECH extrusion head technology means that you benefit from gains in material savings, precise pipe and tube dimensions and quality, simplified maintenance operations and operator efficiency. Expand your product range and production performance with a Maillefer extrusion head when upgrading components, or when beginning to consider a complete extrusion line.

Rémy Kohler

Sales Administrator Pipe & Tube

remy.kohler@maillefer.net

Topics: Maillefer Services, Upgrade Solutions, Extrusion, Pipe & tube manufacturing

Plastics have gained a significant place in today's automotive industry. There is a variety of multi-layer tube & pipe constructions, from ...

Read moreSynergies and partnerships translate to more extrusion systems, and now include multi-lumen, TPE materials, and triple layer co-extrusion alongside ...

Read moreThe ECH 3/20 single layer extrusion crosshead is for production of corrugated tubes, especially for automotive and technical applications.

Read more