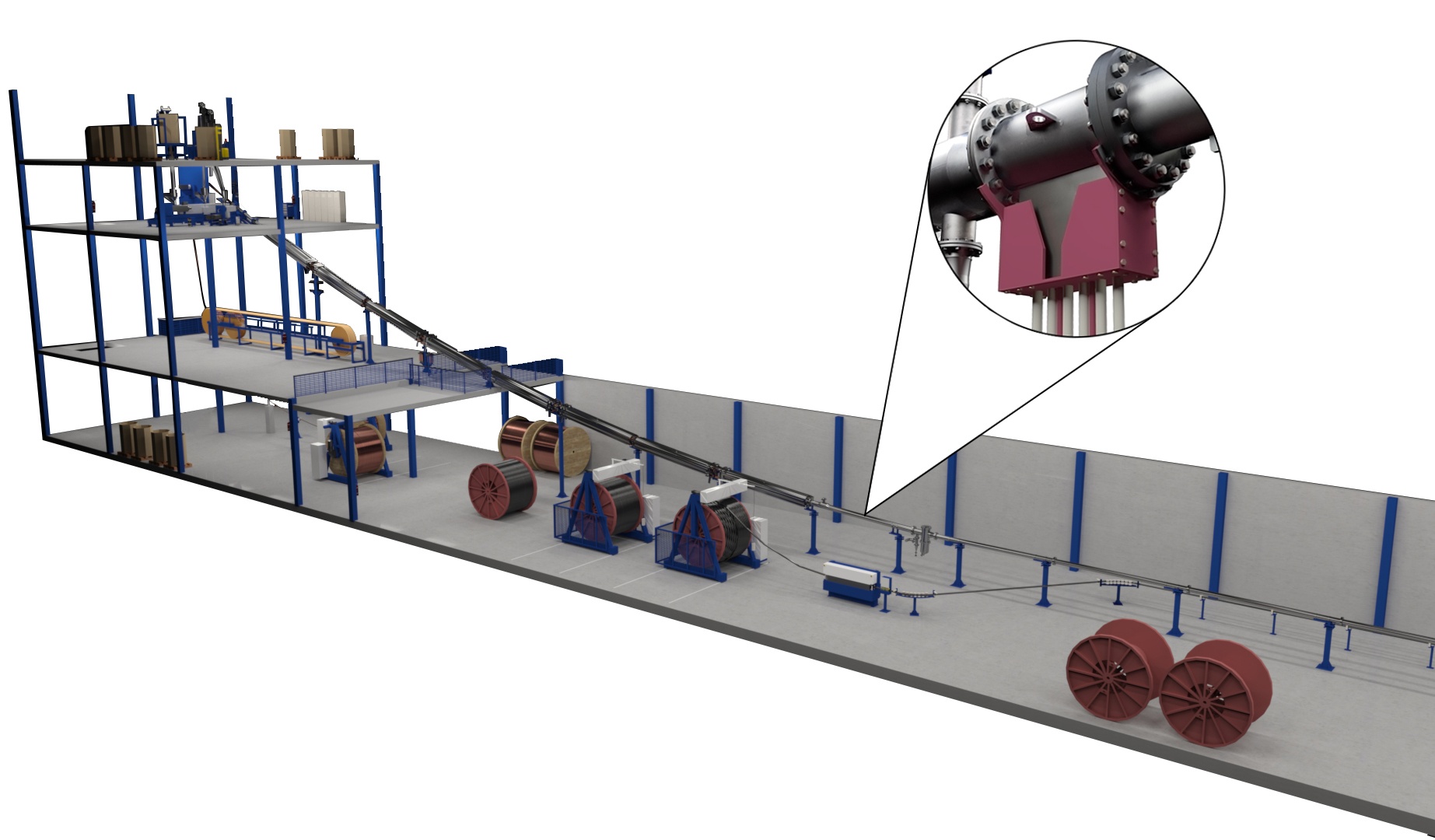

Are you looking for higher productivity and performance in your medium, high and extra high voltage cable production? Our Neutral Zone Post Heating is a new method to accelerate line speeds in our EPL 50//Extend and EPL 50///Explore lines.

In conductor heating by induction just before and after the crosshead, the rapid increase in insulation temperature reduces the insulation viscosity and significant drooping occurs causing the insulation layer to be off-centered.

We have invented a new method – Neutral Zone Post Heating to increase heating and crosslinking capacity without the drooping effect.

With our new solution, inductive heating of the conductor is instead placed downstream of the vulcanisation tube. At this point, the crosslinking reaction has progressed sufficiently and the insulation is already partially crosslinked close to the conductor. This allows inductive heating of the conductor in order to accelerate completion of the crosslinking without the drooping effect.

Easy adaptation of the Maillefer Neutral Zone Post Heater and short production stoppages for its set up, enable boosting of also your current CV-line performance and productivity.

Jorma Leppänen, Product Manager, MV/HV/EHV Cable Solutions

jorma.leppanen@maillefer.net

Topics: Product quality, Production Capacity, Novelties & Launches, Wire & cable manufacturing, Innovation

Our new High Voltage Catenary Continuous Vulcanizing Line EPL 50/Enter is a versatile and economical high voltage CCV line for XLPE insulation and ...

Read moreNKT in Karlskrona, Sweden has acquired the 550th CV line built by Maillefer and the 250th one dedicated to High-Voltage cable. The primary purpose of ...

Read moreImagine a CV line automatically gearing itself for production of high-voltage and extra high-voltage cables only by selecting the desired product. ...

Read more