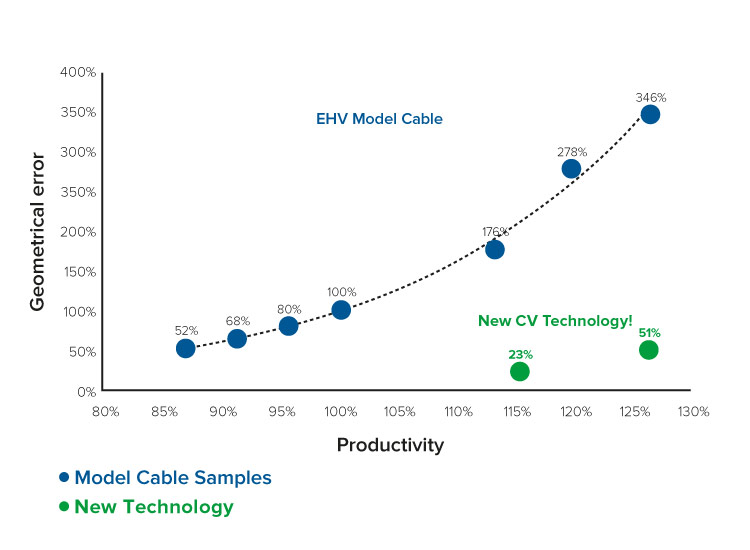

Would you also like to have 20% higher line productivity in your VCV line? It is possible with our new patent pending curing technology - the Round Value Package Premium.

Based on the extensive studies made with our Vertical Pilot Line, we have been able to make a breakthrough in CV technology. Never before have we seen such drastic improvements in productivity coupled with increased product quality.

We have tested the new Round Value Package Premium on our Vertical Pilot Line with several high and extra high voltage cable constructions, up to 500 kV, and all have shown excellent results.

We are currently in the process of piloting the value package on a customer VCV line and expect the results to be just as extraordinary.

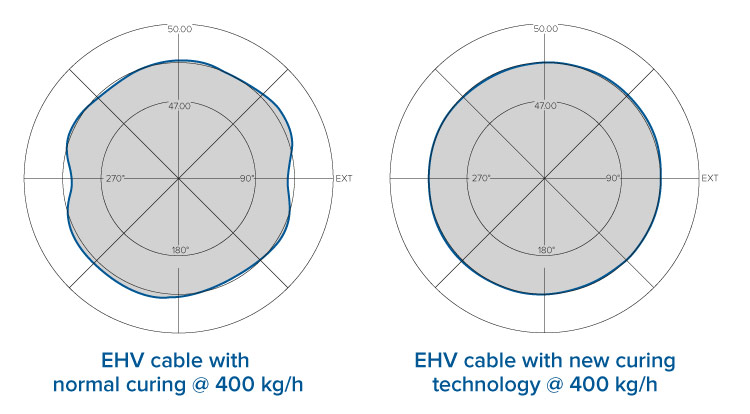

Optimal roundness is essential for efficient use of insulation material on a CV line. Cutting down on material overuse can lead to major cost savings throughout a yearly production. Insulation material saving is not the only cost benefit. Material savings are even greater in the subsequent processes, like in the case of lead jacketed cables where savings can reach up to 500 k€ per year!

Roundness is also vital for pre-molded and pre-fabricated joints and terminations. Constructing cable joints is much easier when the cable core has excellent roundness. It also improves the longitudinal water tightness between the lead sheath and cable core.

Jorma Leppänen

Product Manager, MV/HV/EHV Cable Solutions

jorma.leppanen@maillefer.net

Topics: Product quality, Production Capacity, Production cost, Wire & cable manufacturing, Innovation

Are you looking for higher productivity and performance in your medium, high and extra high voltage cable production? Our Neutral Zone Post Heating ...

Read moreDalian Jinzhou Cable’s first rubber cable production line from Maillefer is up and running. After a busy year of 2013 with numerous 10 kV cable ...

Read moreWould you like to significantly cut costs in your medium voltage rubber cable production? With Continuous Type Change (CTC) it is possible. The ...

Read more