Are you interested in developing your cable production facility? Do you struggle to achieve process performance targets? Maillefer's SimFactory addresses these questions and more.

Are product lead-times, utilization rates, or overall efficiency in need of improvement? Do you have a vision to enable new business by a production expansion? Do you face challenges in evaluating the feasibility of equipment investments or new arrangements in the production? SimFactory reveals solutions.

SimFactory is a comprehensive toolbox that helps find ways to improve your production and earn more. It is based on a systematic optimization process and 3D plant simulation software. Simulation mimics the behavior of a defined system and is based on a model that describes the system at an appropriate level of detail.

Maillefer has developed a simulation platform with a specific configuration considering the needs of cable manufacturing. It allows flexibility in the means of production principles, for example, bulk vs. individual or push vs. pull production control. Every process and resource is modeled with real parameters. They can be monitored for productivity, efficiency, cost, etc.

Simulation is used today in many industries, especially in the unit goods industries and serial production. Many of the leading companies in the world do not implement production improvements without first running simulations. Tests and simulations in a stress-free virtual environment help to identify the possible issues and needed improvements before costly implementation.

Our optimization process is built on the well-accepted Lean Six Sigma road map called DMAIC (Define, Measure, Analyze, Improve and Control). DMAIC is a data-driven improvement discipline for improving, optimizing, and stabilizing of business or production processes and designs. Every successful development project is based on good teamwork. Therefore the team pools together experts from both customers and Maillefer. This generates the kind of commitment needed to succeed from key persons participating in the process.

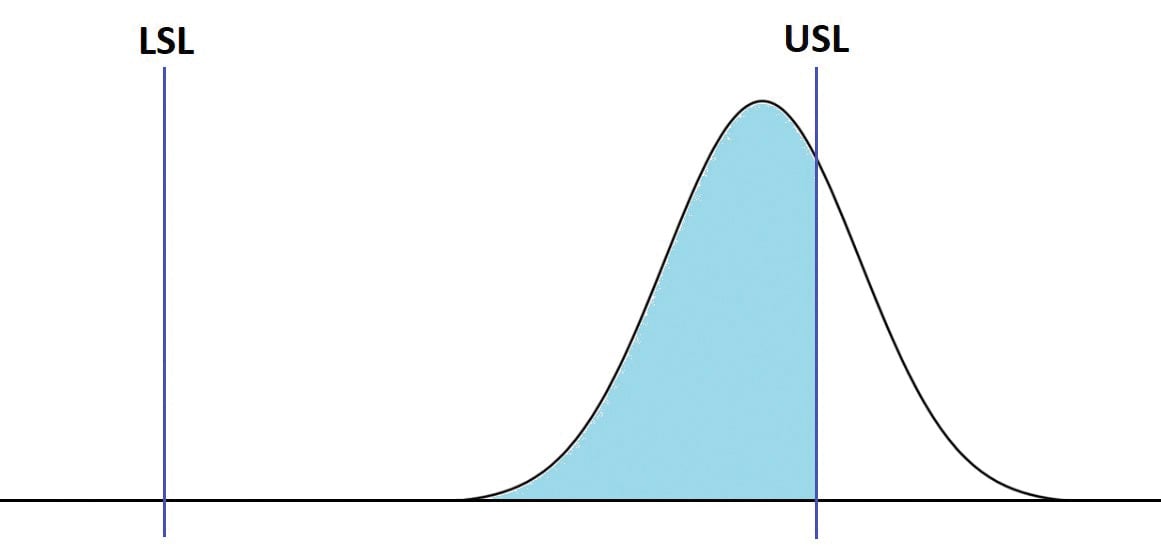

The Define phase sets the scope of the project, identifying what specifically needs to be improved and why. During the Measure phase, data is gathered, all processes mapped and an intelligent model defined in the 3D plant simulation software. After this, the right metrics (eg. lead-time, quality, utilization, etc.) are chosen and the plant initial capability is measured. The calculations use the standard deviation of the measurements compared to the specification limits. Well preparing these first two phases enables the best results during the following steps.

Figure 1: Example of plant initial capability. The process main metric (eg. lead-time, quality, utilization, etc.) is out of range of defined LSL (Lower Specification Limit) and USL (Upper Specification Limit)

The Analyze phase serves to identify the potential for improvement through dynamic 3D plant simulation that uses input parameters and a chosen production plan. Metrics reveal problems and inefficiency, like bottlenecks that prevent your manufacturing capacity from performing optimally.

The simulation is an iterative process involving multiple steps. It is run by adding constraints and complexity step-by-step. This way the current state is gradually analyzed. The target is to find the processes where there is unused potential and which will benefit most of the improvements.

During the Improve phase, the improvements are introduced to the simulation model and the metrics are used to indicate the results. All potential for possible upgrades and replacements are considered.

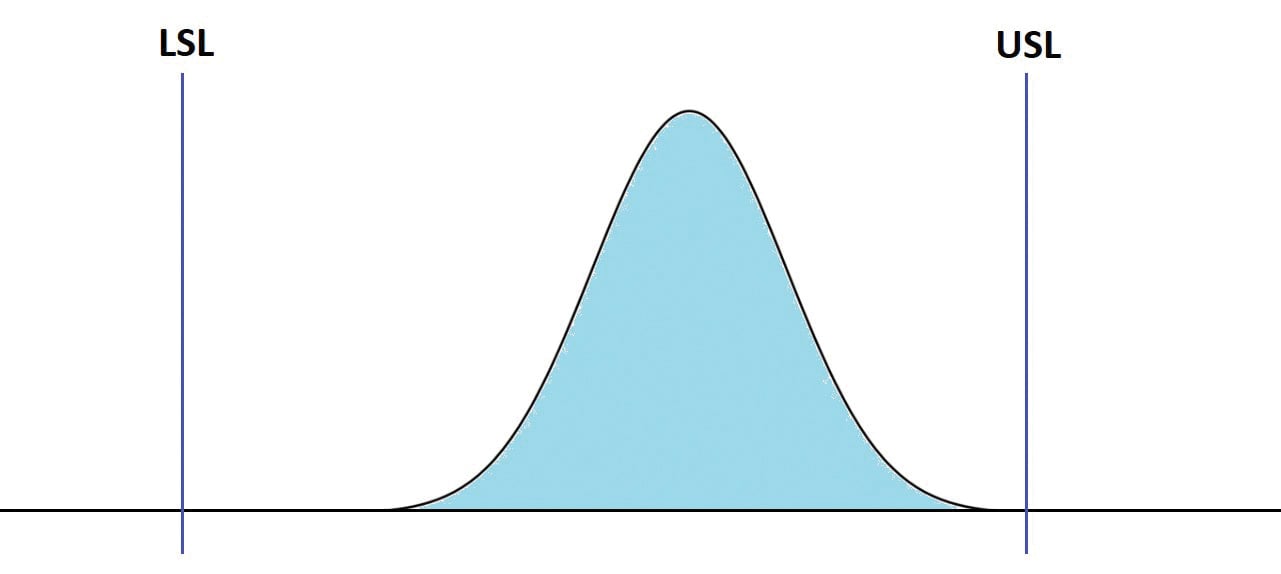

After the bottleneck process is found, the production flow can be improved within the limits of processes upstream and downstream. When the improvements in flow are insufficient, equipment needs to be modernized, replaced, or increased. The plant improved capability is defined with simulation verified results. At the end of this phase, Maillefer delivers a report including current state analysis, before and after scenarios, and a comprehensive optimization plan that details short-term and long-term improvement actions.

The final Control phase includes one or two follow-up workshops. The first takes place within two years after delivering the report. The recommended actions taken are reviewed and the results verified against expectations.

Figure 2: Example of plant improinitial capability. The process main metric (eg. lead-time, quality, utilization, etc.) is out of range of defined LSL (Lower Specification Limit) and USL (Upper Specification Limit)

Maillefer accompanies clients in continued improvement cycles through further reviews, new scenarios, and updated simulations with fresh results. It is through tools like the SimFactory that you can best focus your efforts towards the continued optimization of your factory.

Juha Hiltunen

Director, Project Management

juha.hiltunen@maillefer.net

Tapani Savolainen

Plant Definition Consultant

tapani.savolainen@maillefer.net

Topics: Performance solutions, Maillefer Services, Maillefer, Performance, Upgrade Solutions, Value Corner, Novelties & Launches, Extrusion, Wire & cable manufacturing, Smart Factory, Digitalization

There is a cutter for each Pipe & Tube application that Maillefer delivers. Cutting design, safe access, and ergonomic handling all play their ...

Read moreWe've positioned ourselves as technology leader in plastic extrusion having the widest systems and services portfolio for the global wire, cable, ...

Read moreThe long standing reputation of Maillefer as a full service provider comes in part from our history in empowering customer staff with knowledge ...

Read more