We're actively developing our solutions for medical since announcing features like pre-cut and short lengths one year ago. Now, we've concentrated on upping line speeds without sacrificing quality. There are improvements to extrusion flow thanks to screw design and extrusion head; plus optimized cooling, from the extrusion head to leaving the water bath. Gains in factory-wide performance and product optimization bring results across all manufacturing steps, especially for assembly located downstream.

Philippe Giovangrandi

Technical Sales Director, Pipe Solutions

philippe.giovangrandi@maillefer.net

Topics: Medical tube

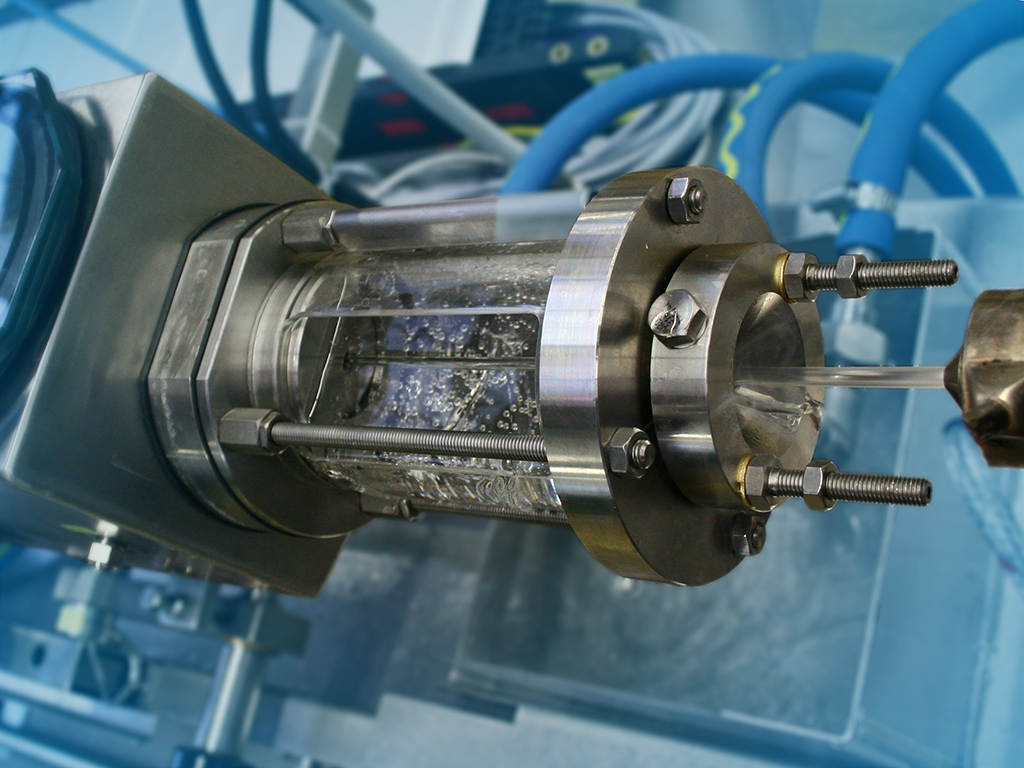

Maillefer has a complete program of extrusion heads which fulfils the needs for pipe & tube manufacturing. Typically proposed in our line ...

Read moreOne of the many challenges in the medical device industry is the production of plastic PVC or PU tube. Two optimization methods for flexible tubing ...

Read moreMaillefer announces features for its PML extrusion lines for the production of soft PVC medical intravenous (IV) tube. Thanks to cooperation with the ...

Read more