The world’s sole vertical pilot curing line for high and extra high voltages cables is available in our R&D Center in Finland. The line is equipped with a full scale extrusion group capable of producing model cables up to 550 kV and beyond at realistic line speeds.

The full scale facilities make it possible to develop the cable production process as a whole. For example, various cable quality issues are only visible after the curing process. Previously, such issues could only be studied with test runs on customer lines. It was, however, difficult to schedule, time consuming and very expensive for all parties. Our vertical pilot line makes it possible to do model cables at an unprecedented pace!

The material need for a model cable on our vertical pilot line is significantly lower compared to a trial run on a real production line. One metric ton of insulation material is enough for up to six samples. This makes it possible to do comprehensive development together with customers and material suppliers under very cost effective and virtually risk-free conditions.

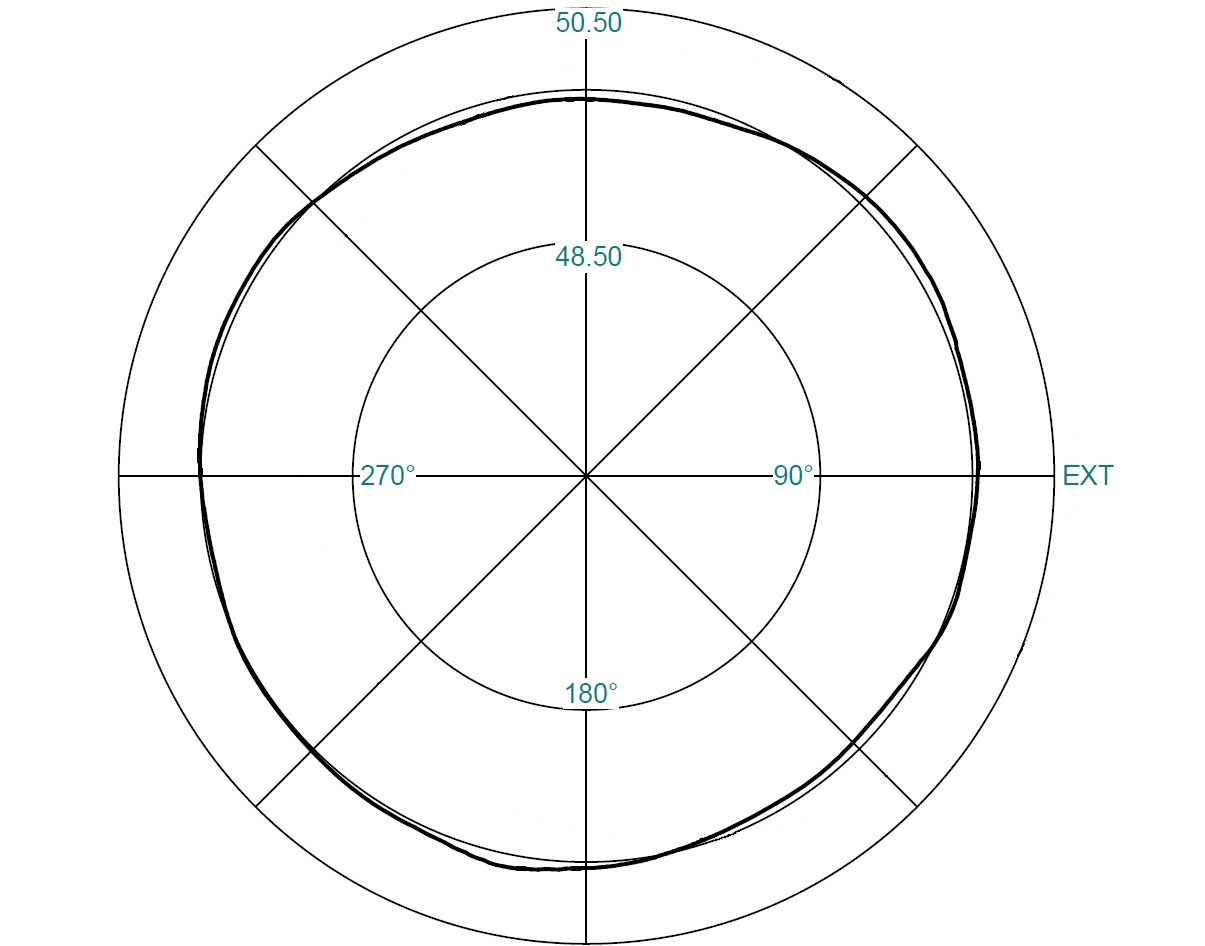

The vertical pilot line offers a unique opportunity to study the cable manufacturing process as a whole. These trials have offered us more detailed understanding on the nuances of the factors affecting the cable roundness. As a result, we have far exceeded the industry standard roundness level of 0.990 Dmin /Dmax and are instead capable of producing high and extra high voltage model cables which have roundness levels of over 0.998.

A Maillefer roundness measurement result of a model cable with a roundness level of over 0.998 Dmin/Dmax

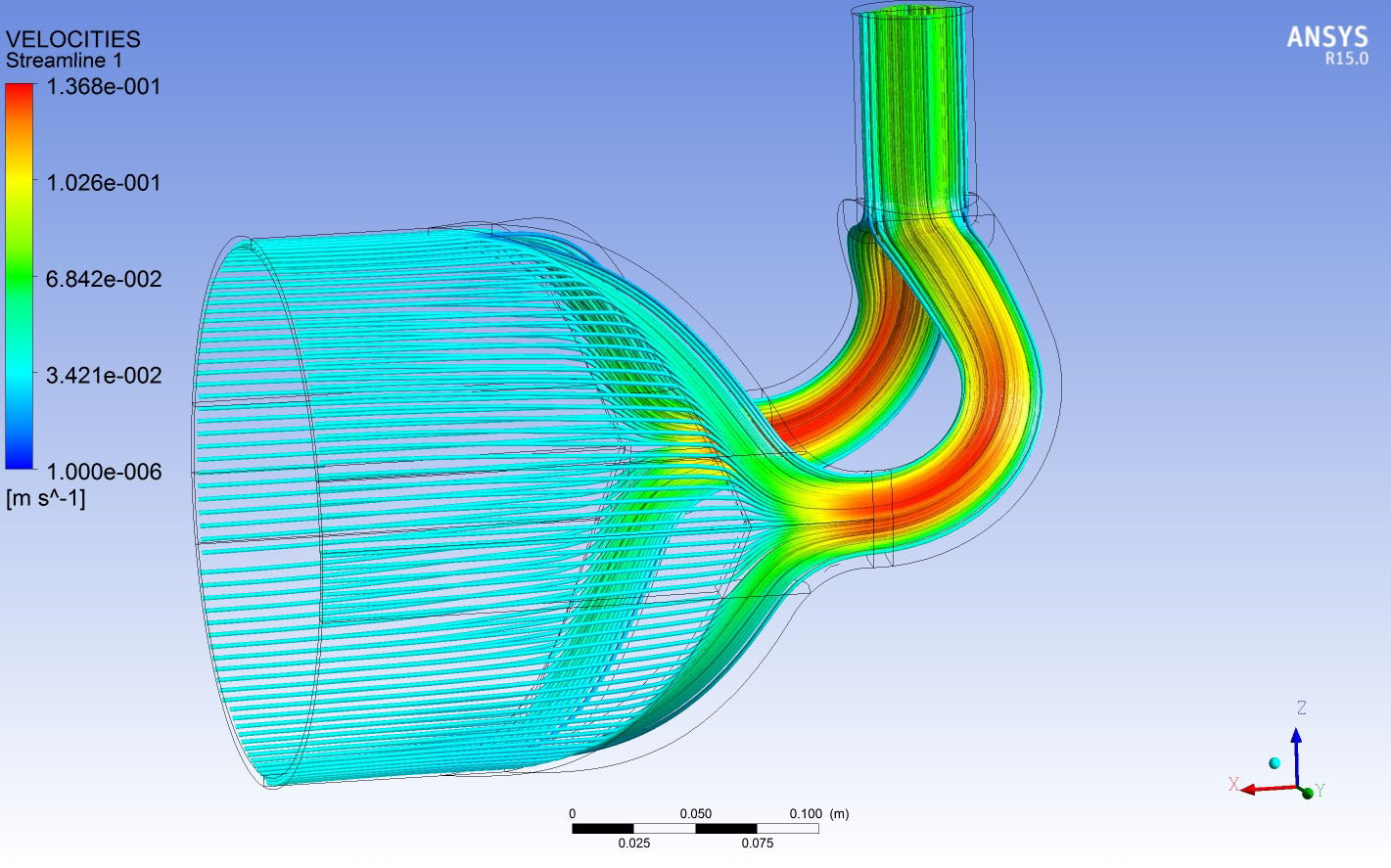

The vertical pilot line accelerates the development cycles of both extruder heads and screws. Simulation models are updated continuously based on the real test results. This operating model has created an extensive understanding of the polymer flow behavior and elimination of stagnation prone areas in both the screws and distributors. This is just one example of how we can support our customers to explore their limits.

Excellent flow distribution analyzed with CFD software.

Mikko Lahti

Director, R&D

mikko.lahti@maillefer.net

Topics: Performance solutions, Product quality, R&D, Wire & cable manufacturing, Innovation

All cable manufacturers know that joining a conductor in a CV line within a limited time frame is very challenging. We offer a method to make ...

Read moreImagine a CV line automatically gearing itself for production of high-voltage and extra high-voltage cables only by selecting the desired product. ...

Read moreNKT in Karlskrona, Sweden has acquired the 550th CV line built by Maillefer and the 250th one dedicated to High-Voltage cable. The primary purpose of ...

Read more