In the old days, cars were built with fewer parts. Nowadays, the number is climbing into the tens of thousands. For the extrusion industry, that translates into opportunity.

An incredible amount of technology is tucked away under the hood of today’s vehicles, largely boosted by the volumes of EV and EHV being produced. Plastic and elastomer components are everywhere. The multiplication of pipe, tube, hose, wire, cable, and conductor bars as well as profiles, films, and blown molded parts are providing more work and new challenges to the industry. As a tier 1 supplier, where can you turn to help produce today’s quality products for your OEM clients(s)?

The good old days?

The early years when automotive parts numbered in the low hundreds are gone by. Components then were of basic design and under fewer constraints. We didn’t need to worry so much about emissions, vehicle weight, fuel consumption, or fancy gadgets. A big enough powertrain compensated for inefficiencies and encouraged generations of drivers to hit the open road. Yes, there were reliability and quality issues. But with a simple toolbox and some elbow grease, you could fix those up in a jiffy, right at home.

Nowadays, you don’t dare lift the hood or, you may need to refer to the e-manual first. Push or pull in the right way with the car’s RFID key in range, and you may be lucky. Today’s vehicles are packed with electronics, power & transmission, emission, safety, climate, communication, driver assistance, guidance, security, and multi-media, just to name a few of the systems built in.

Parts in the thousands

Vehicles driven by electric, hybrid, or fuel cell power hold much market potential, in contrast to the combustion engine, which faces ever-tightening restrictions. The number of parts that go into the making of a car, is climbing into the tens of thousands. Even considering a tiny percent of those concerned by the extrusion and coating processes, that translates to a few hundred components.

Today’s parts are made from a growing list of thermoplastics and elastomers like PE, PVC, PA, PP, TPU, TPE, Silicone, Rubber, and specially engineered compounds. Each material type is chosen for the specific characteristics and functional features it provides (e.g. mechanical, weight, chemical, temperature resistance, barrier capability, geometrical, etc.).

A sizeable offering

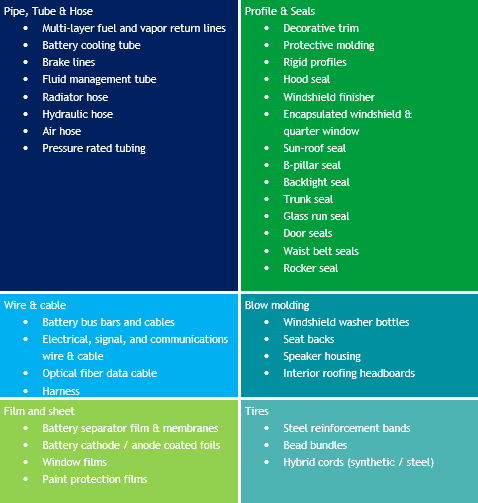

Highlighted below, is a sampling of automotive parts produced through different processes where we have provided solutions.

A portfolio in response

With the catalog of parts increasing together with the design challenges, so does the job of making them. Getting solutions to all your manufacturing needs from one source in today’s automotive universe may be a bit idealistic, but you can certainly count on Maillefer together with Davis-Standard as reliable partners. We’ll help you maximize the potential amongst the hundreds of options to choose from.

André Gosselin, Marketing Manager

marketing@maillefer.net

Topics: Elastomers, Maillefer, Wire & cable manufacturing, Digitalization, Pipe & tube manufacturing, Rubber, automotive

The wire show in Shanghai was a success for the Maillefer team. We met nearly all our existing and several new potential customers from China. We ...

Read moreManufacturers of plastic products recognize that lots of energy is needed to form their product. It is provided in the way of electricity. Electrical ...

Read moreOnce more Shanghai hosted the Chinese cable industry as well as many other international players. The exhibition was more international than ever ...

Read more