Vertical pilot line at Maillefer R&D Center in Finland

Vertical pilot line at Maillefer R&D Center in Finland

Production length is the determining factor when selecting the line speed and production time, leaving a relatively small window of operation. Long production lengths lead to high line speeds and thus demanding production conditions.

This spring we conducted a joint development effort for the optimization of process conditions for our customer’s VCV line producing high voltage cables. He faced sizable challenges with a new cable construction. They had produced a test cable with unsatisfactory geometrical quality. Together we organized a trial program for process optimization on our pilot vertical line in Finland.

We started by replicating the VCV line configuration and process conditions used for the customer’s sample and compared it to our pilot vertical line cable sample. The fully cured pilot sample had an extraordinarily close correlation with the customer’s original sample. Excitingly, we had succeeded in replicating the insulation geometrical error!

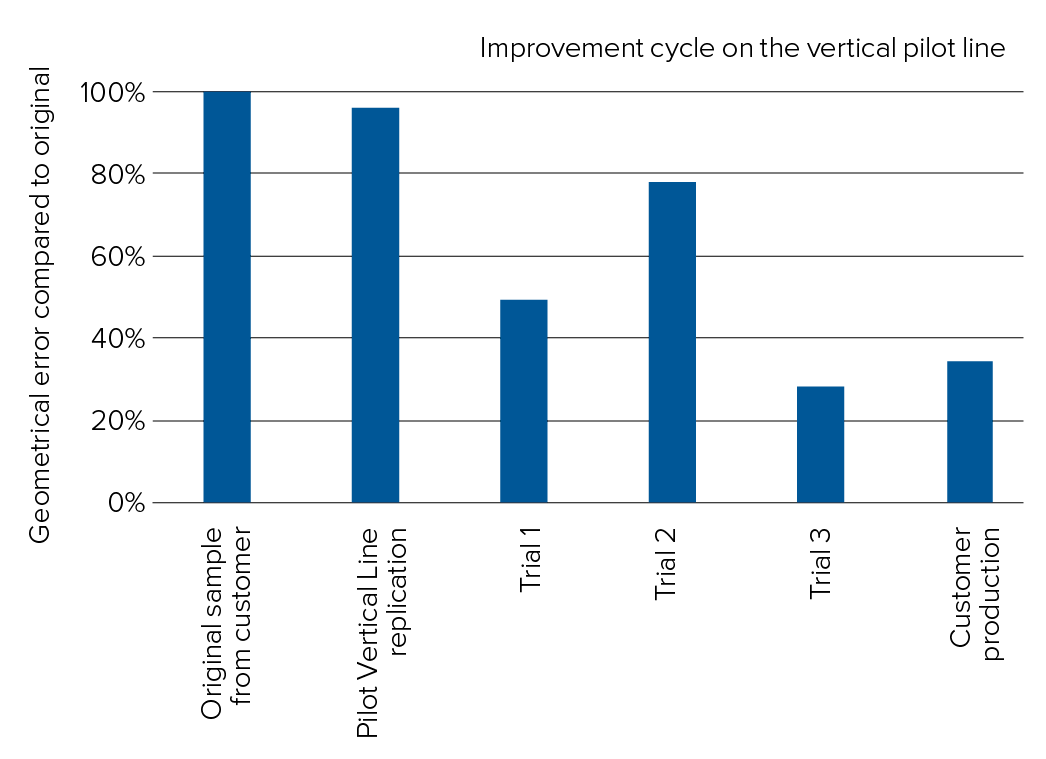

Once the full trial program completed, we had a good model of the cable’s geometrical quality with the specific cable construction and the specific customer production line. The geometrical error measurements from the trial are shown in Figure 1.

Figure 1. Reduction of geometrical error beginning with the customer’s original samples

Based on the trial results, the optimal production conditions were chosen for the cable production program. The customer then launched their program with the optimized process conditions. The results showed a drop of 60% in geometrical error on their final product. Better roundness of the produced cable core enables significant material savings in the insulation process as well as in the subsequent processes.

Everyone involved with the project was amazed by the accuracy of the results produced on the pilot vertical line and very pleased with the final results. The customer got unprecedented data on how to plan their production parameters without the need to occupy their production line itself ! With just one week’s effort at our R&D Center they could verify the production conditions for a whole new cable construction with ease.

There are many perspectives to consider when optimizing the production of a cable factory, of which the cable core insulation process is a crucial part. In this case, the effort focused on finding the right balance between the following:

Our vertical pilot line makes it possible to produce model cables at an unmatched pace. As a result, you return home with winning productivity and manufacturing practices.

Janne Harjuhahto

R&D Engineer

janne.harjuhahto@maillefer.net

Topics: Product quality, R&D, Production Capacity, Production cost, Wire & cable manufacturing, Innovation

Would you like to significantly cut costs in your medium voltage rubber cable production? With Continuous Type Change (CTC) it is possible. The ...

Read moreWhat’s to be expected from today’s extrusion manufacturing provider when investing in production capacity or when looking to improve performance ?

Read moreOur NCC curing calculation tool migrates to an easily accessible web-based software. Optimize production speeds and share simulations between sites ...

Read more