The novel insulation screw SM7 is designed to reduce scorch risk by minimizing stagnation points. It is an evolution of the well proven SM5 design of which we have delivered into more than 200 insulation extruders globally.

Good subsea cables are all about a minimum number of joints and easy underwater installation. Subsea cable production is an excellent example where long production lengths are vital to minimize the number of cable joints. With our Long Run Value Package you can increase continuous production lengths up to 80% without stopping the line. All this has a direct impact on your productivity. The value package consists of our novel SM7 insulation screw and THX 70/150 LR triple crosshead.

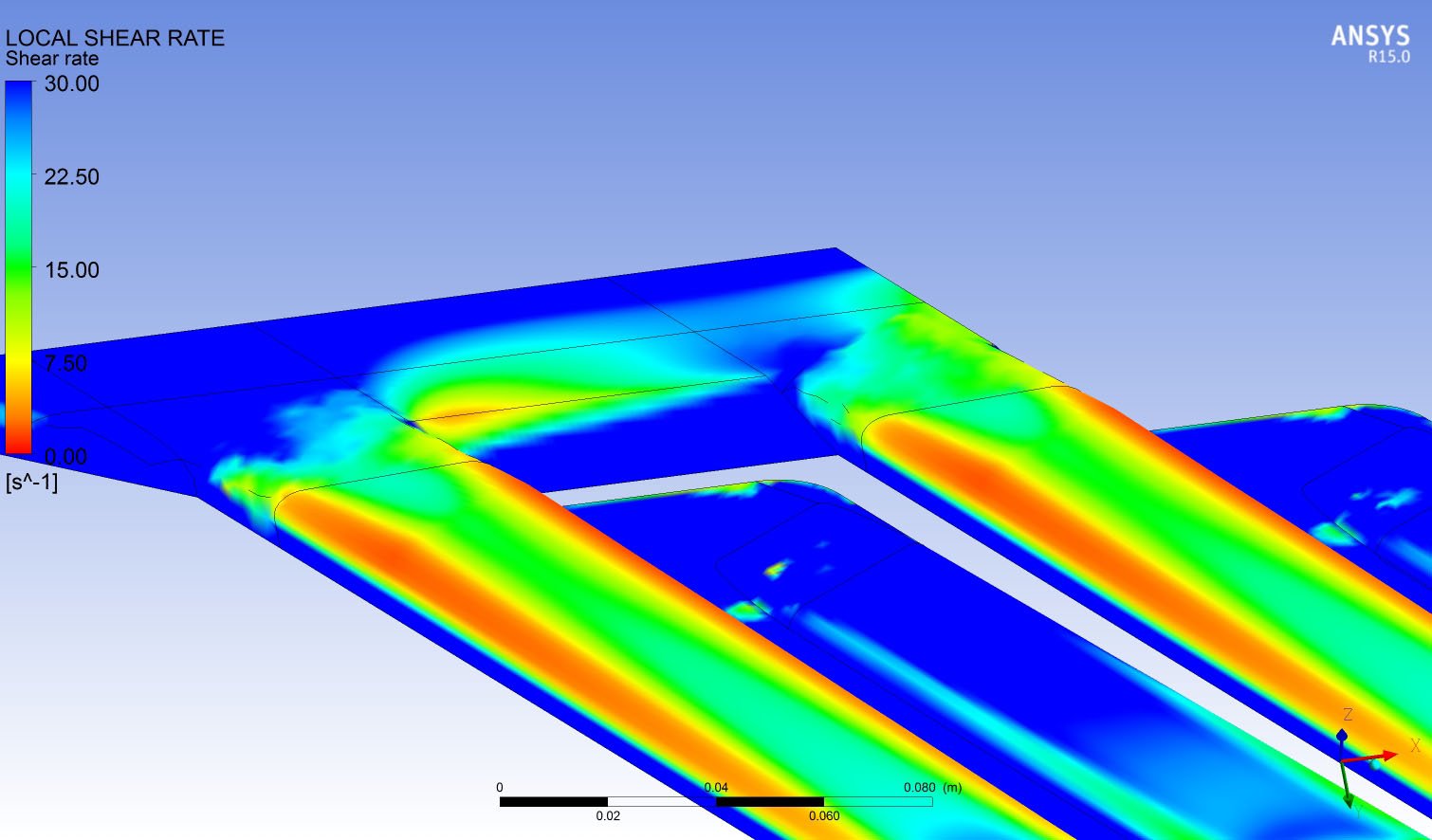

The novel insulation screw SM7 is designed to reduce scorch risk by minimizing stagnation points. It has a much higher specific output than our earlier screws and thereby a lower melt temperature. The new SM7 screw results in a 50-80% increase in insulation lengths (measured in tons).

The triple crosshead THX 70/150 LR has been developed to enable longer production runs by improved material flow and temperature control. The key improvements compared to our standard triple crosshead are shorter material residence time, minimized stagnation risks, increased water tempered area, and improved distribution.

Jorma Leppänen

Product Manager, MV/HV/EHV Cable Solutions

jorma.leppanen@maillefer.net

Topics: Performance solutions, Product quality, Production Capacity, Wire & cable manufacturing

With the growing demand for thermoplastic extrusion, the new MXI series expands the range, with extruders from 80 to 200 mm, for insulation or ...

Read moreThe topography is a novel solution for cable quality control during production. The original idea to develop such a device was sparked many years ago ...

Read moreAttain concentricity levels of 97% and more with the ACDH auto centering extrusion head for cable insulation or jacketing. Adjust wall thickness ...

Read more