MED 3.0 is Maillefer’s web-enabled technical documentation and part identification resource. No more paper binders with outdated references. MED is a sustainable and reactive solution proposed through Maillefer Services.

MED 3.0 is available to customers with equipment delivered from Maillefer. Ease in navigation, searching, and connecting to related information is more than ever possible. Because MED is dynamic, changes we bring about on the parts list are reflected directly to the users.

MED documents are text searchable and contain cross references, bookmarks and other navigational aids for the comfort of users. This program is also an online tool, which means that future changes to the associated Bill of Materials are integrated into the MED database. Messages invite users to replicate the modifications in order to have the most recent documents and parts for their particular equipment.

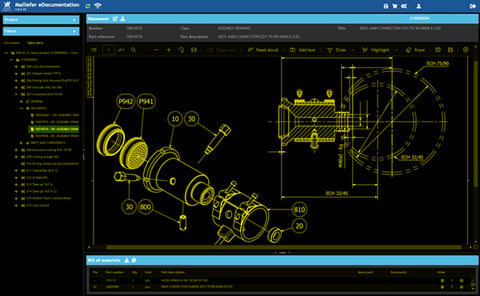

The application presents itself in two modes. A Documentation mode that covers all the technical descriptions and drawings related to the project, and a Spare Parts mode that offers access to individual parts for easy identification. Users can move between modes using the specific information at hand (e.g. a part found in a drawing shown can be directly added to the spare parts request.)

A customer installation is represented hierarchically in MED. Its tree structure provides a synopsis of supply with branches leading to individual components in the line. Each machine typically has four categories of documents associated with it: general information (instruction manuals); mechanical drawings; electrical schematics; and original documentation for various integrated parts and components coming from OEMs (e.g. motors, gear boxes, drives, etc.)

The Spare Parts mode lets the client see all the spare parts identified by Maillefer for each machine. There is a distinction between recommended parts, safety parts and wear parts.

The search tool is used to display the specified part on the corresponding engineering drawing. A parts table associated with the drawing allows you to collect items into a basket, from where you can directly e-mail Maillefer Services to request a quotation.

When customers opt for MED to facilitate transmission of a parts request, Maillefer Services treats the request as a priority, meaning that the ordering process is shortened. Furthermore, the request process inherently assures that you order exactly the parts that you need.

MED 3.0 is a web-enabled, screen responsive and multi-platform application, which is fit for hand-held devices as well as desktop and laptop computers. Turning to MED means experiencing the efficiency gains of quickly accessing the technical know-how and specifying the right parts for your Maillefer installation.

Lysenko Balderrama

Ecublens Service Manager

lysenko.balderrama@maillefer.net

Topics: Product quality, Support Services, Maillefer, Performance, Value Corner, Extrusion, Smart Factory, Innovation, Pipe & tube manufacturing

The latest version of the Maillefer documentation software is here, MED 3.0. The web-enabled documentation utility makes finding assemblies and ...

Read moreThe Stronger Together slogan is a reality for Maillefer, a member of the Davis-Standard group of companies. A case in point is the welcome arrival of ...

Read moreAt Wire Russia 2019, Maillefer takes the next step in the digitalization of manufacturing and introduces the Smart Factory. With the Virtual Reality ...

Read more