There are several thousand of Maillefer extrusion lines and components currently producing for a large range of applications. Some may be yours. Turn to us to help keep them running at optimum levels.

Over the decades, Maillefer has produced several thousand extrusion lines and components for a large range of applications. Through equipment monitoring and regular maintenance of components, high system performance and output levels are possible.

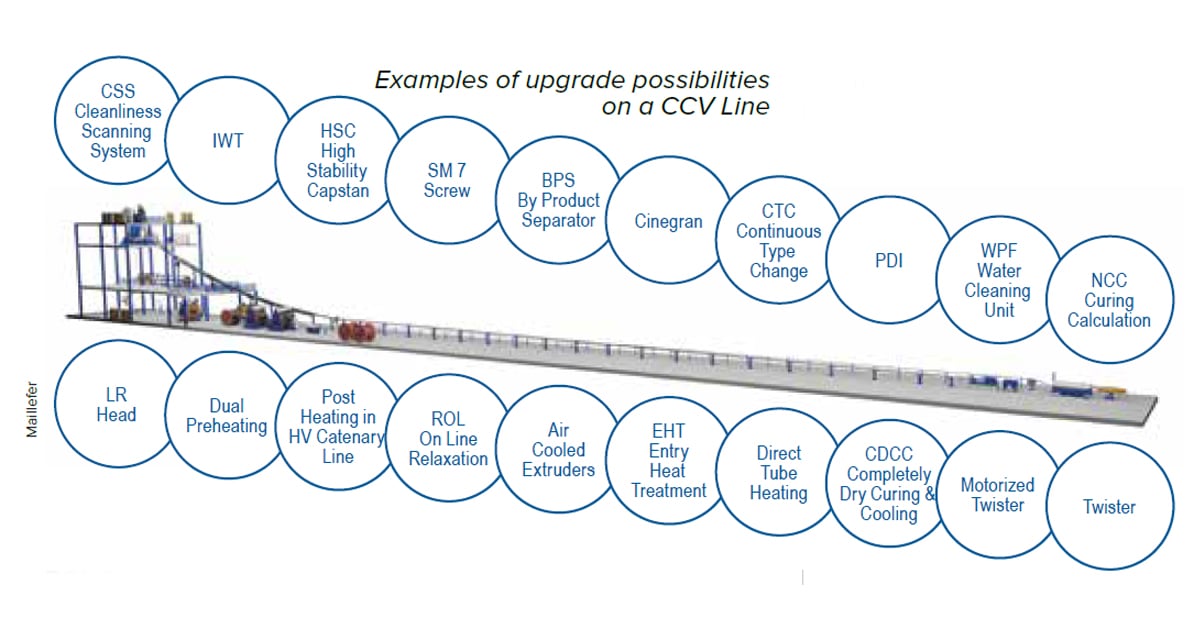

Expect that components need a technology upgrade or have to be completely replaced in order to maintain or exceed original performance. In the following, we highlight certain actions that can be taken on Maillefer Wire & Cable production systems.

Basically, any line can benefit from our extensive upgrade opportunities. Depending on the type of needs you have, there are new replacement solutions in place and ready for you.

PSU6 and Remote office

Secure the line’s operability with an up-to-date Process Supervision Unit (PSU). Version 6.0 utilizes state-of-the-art hardware and software applications, and open architectures. You get unlimited access with the best data analysis tools and many smart utilities. Remote office gives you the flexibility to analyze the data, prepare recipes and download them from your own office, or from a remote location.

Gas Circulation Blower - PMM 100

Maillefer’s novel Gas Circulation Blower PMM 100 further increases the reliability of producing MV and HV cables. PMM 100 has been specifically designed for gas cooling circulation units in both CCV and VCV lines.

Instead of employing mechanical seals that are subject to failure, our Gas Circulation Blower is based on the principle of a permanent magnet motor, which requires none. The PMM 100 also enables significantly longer maintenance intervals compared to a conventional blower, thanks to its closed structure.

IWT – Integrated Water Tempering unit

Maillefer’s water tempering unit meets the specific demands of the extrusion process. A reliable and accurate temperature control, in addition to continuous adjusting and monitoring of the extrusion process, is a guarantee for high quality three layered cable core.

Rely on a system that is best suited to HV, EHV and submarine cable extrusion processes, where temperature stability and reliability is critical.

The Integrated Water Tempering unit (IWT) is a fully integrated part of the line control system. Tempered water circulation of the extrusion screws and the crosshead flow channels are controlled as accurately as the individual zones of the plastic insulation extruders. The water tempering can be monitored, adjusted and controlled directly from the line control computer.

Get the most out of your installed capacity. Turn to Maillefer for the extra boost that will keep you up and running.

Roger Möller

VP Maillefer Services

roger.moller@maillefer.net

Topics: Uppgrade solutions, Product quality, Support Services, Maillefer, Performance, Maintenance solutions, Extrusion, Wire & cable manufacturing, Innovation

Run Times Reach New Heights The performance of extruded high voltage XLPE insulated cables is improvable by reducing the degassing burden and ...

Read moreMultipurpose Lines Help Lead the Way for PP Cable One of the new trends in power cable manufacturing is the rise of PP (polypropylene) based ...

Read morePolyhose India is a manufacturer of thermoplastic tube, spiral and cross braided high-pressure hydraulic hose, PTFE hose and PVC braided hose for ...

Read more